Subsea Oil & Gas Case Study

When Inuktun received an urgent request for remote visual inspection equipment which would enable their oil & gas client to assess the damage on a bent and buckled subsea pipe, it only took a month for the robotics company to design, manufacture and test a customised solution.

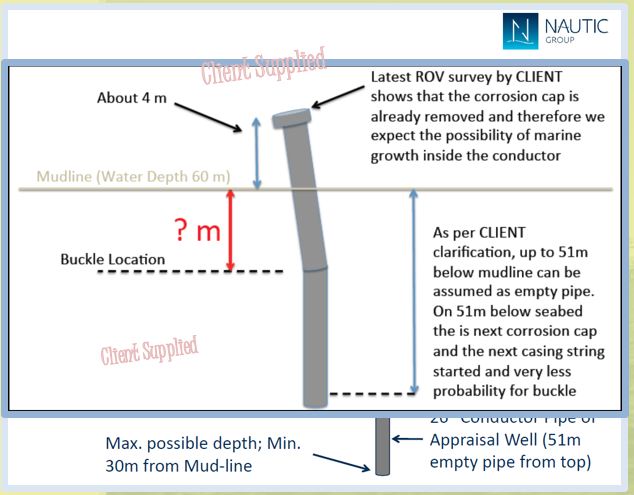

The request had come from NauticAWT Ltd (formerly Nautic Group), a firm offering subsurface, subsea and surface facilities, engineering services and contracting solutions for field exploration, field development and field refurbishment including asset life extension and production enhancement for mature and ageing oil and gas assets. Visual inspection was required to assess the damage on the client’s subsea pipe but the nature, extent and whereabouts of the problem were unknown.

The damage was described as being ‘somewhere’ along the subsea pipe up to 51m below the mudline. The client indicated that below that depth, it was likely that the pipe would be empty and the presence of a corrosion cap and casing string at 51m below the seabed meant less probability for buckling.

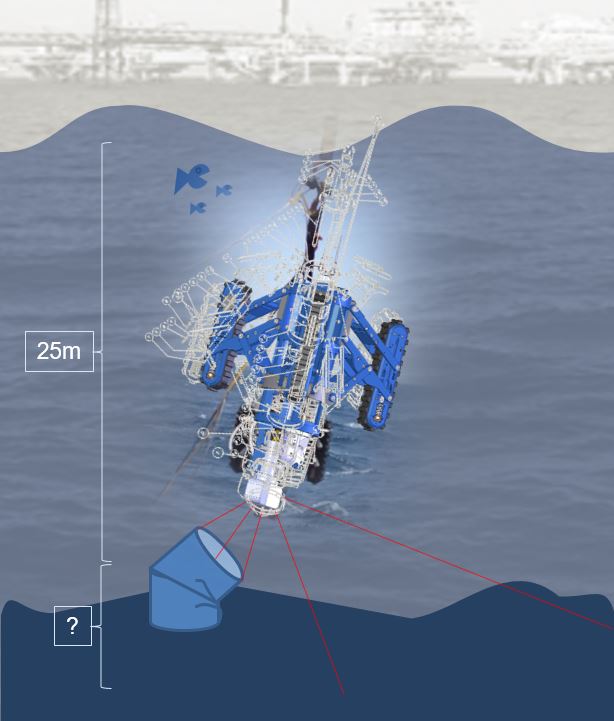

Inuktun’s response to the challenge involved combining one of their VT150TM waterproof vertical crawlers with larger MinitracsTM. These units are individually powered and modular in design so they could be fitted onto the VT150 platform to enable access to confined spaces within the harsh subsea environment.

The equipment was further customised with special spring expansion so that it could traverse the buckle point and self-adjust to any variations in shape of the pipe without any operator input.

Top quality visuals and reliable defect measurements were supplied through the integration of a third party laser scanner and PTZ camera onto the crawler.

This case study illustrates the success of Inuktun’s multi-faceted approach to problem-solving and demonstrates the versatility and performance of their remote visual inspection systems, even in the most inhospitable and challenging environments.

The VT150TM along with an extensive range of other high-performance visual inspection and non-destructive testing equipment are available in Australia from Nexxis – an established industry leader which shares Inuktun’s commitment to developing flexible, practical and affordable solutions to even the most complex industrial challenge.

For more information on the VT150, Minitracs or any other inspection or non-destructive testing device or customised solution, please contact Nexxis on 08 9418 4952 or visit nexxis.com.