Long-Range Pipeline Inspection Case Study

The Problem

When it’s been two and half years since shut down and you have two stuck pigs in a pipeline that spans more than 300 kilometres – you’re facing a really serious challenge. This was the work brief presented to Nexxis recently by a client.

Fortunately, the client estimated that blockages (pigs) were located in a 1.2km span of spool, approximately 43km’s into the pipeline.

Challenge

Long range inspection and custom solutions can be difficult. With long range you need weight to provide traction, torque to be able to power through the pull and overcome friction drag on the tether and an increased voltage to send power over the distance.

Pipe diameter also presents issues, as reduced space and area can compromise the outcome.

Our Solution

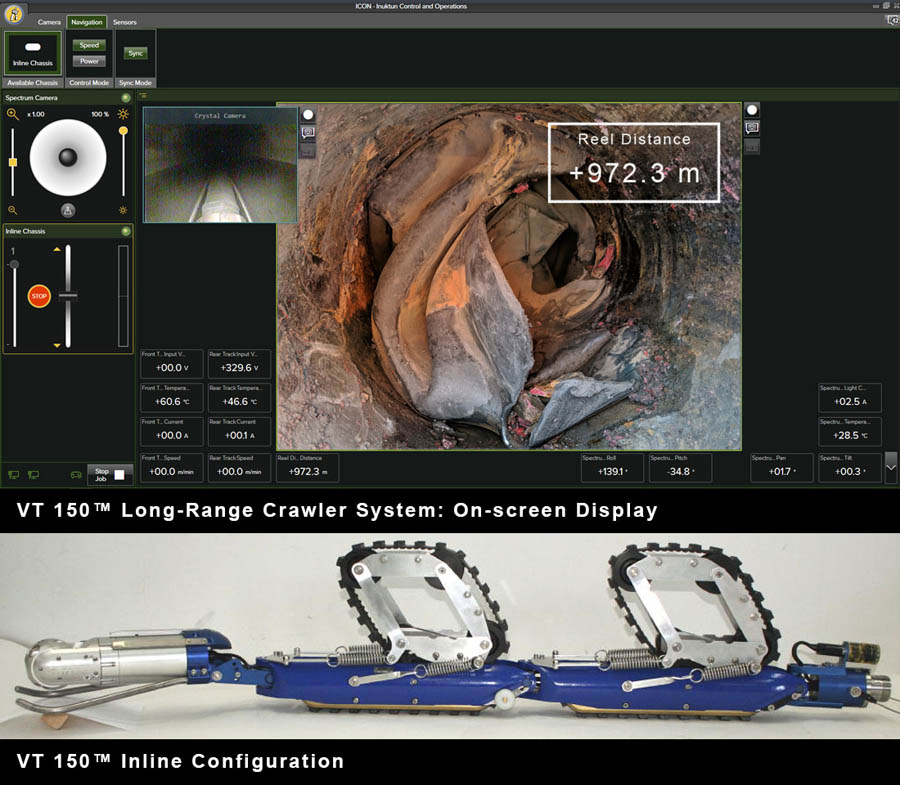

Long-range robotic crawler systems are one of our specialties, and we had the perfect tool available for this job; the Inuktun VT150™ Long-Range Crawler – the only system available in the Southern Hemisphere.

To ensure we meet the customers outcomes on distance and not knowing the conditions of pipe internals we decided to install a spring loaded traction enhancement kit and run the system in it’s Inline configuration. We also fitted an additional weight block to the system to supply significant down force thereby increasing traction.

The VT150™ has advanced camera technology, can be configured for multiple pipe diameters – and most importantly, has an optional 1000 metre tether. This meant we could cover off the 1.2km spans using only two entry points.

On our first entry point, we located a pig at 664 metres and using the high-resolution video and images produced, it was observed that both pigs were at this location, with one having collapsed beneath the other.

With the VT150™ tether encoder giving us an exact distance, the client were able to locate and remove the pigs efficiently and without unnecessary pipeline disruption.

Due to the rapid location of the blockage, the client were then able to inspect an additional 4km’s of pipeline with the longest run being 972 metres. This provided additional high-quality video and still imagery and a good indication of pipeline integrity overall.

Nexxis are always looking to provide custom-fit solutions and on-site specialist support to our clients. If you have equipment needs for your business, get in touch today and let us help.