Powertrain: Revolutionizing Pipeline Inspection and Maintenance

The Powertrain, developed by Nexxis, is a groundbreaking robotic system designed to address the challenges of pipeline inspection and maintenance. This case study delves into Alcoa’s experience with the Powertrain, highlighting its capabilities, benefits, and the successful collaboration between Alcoa and Nexxis.

Overview of the Powertrain:

The Powertrain serves as a vital tool for Alcoa, acting as a reconnaissance mechanism within their extensive pipeline network. By leveraging this advanced technology, Alcoa can proactively identify regions of interest where potential issues may arise, enabling them to take appropriate steps before any significant problems occur. Unlike conventional techniques that rely on external inspections, the Powertrain offers an innovative approach by autonomously navigating inside the pipelines.

Design and Development Process:

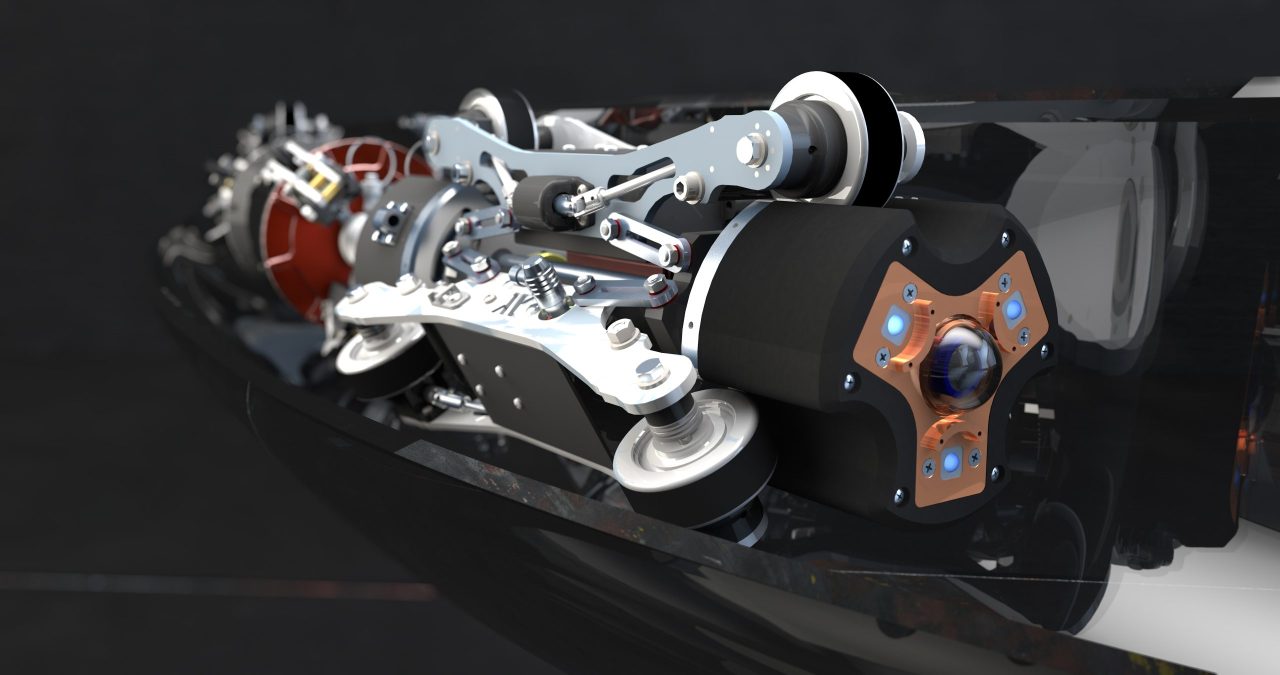

In partnership with Alcoa, the Powertrain developed by Nexxis proved to be a fruitful endeavour. The robotics engineers at Nexxis integrated cutting-edge technologies and built a robotic control system from scratch. The modular design of the Powertrain allows for continuous improvements and the incorporation of different payloads or enhanced drive capabilities, making it adaptable to various pipeline inspection requirements.

Addressing Complex Challenges:

One of the primary objectives for Alcoa was to develop a robot capable of vertically ascending pipelines up to 28 meters high and accessing hard-to-reach areas. The Powertrain was specifically engineered to meet these challenges, incorporating features such as caustic resistance, front and back cameras, and a central unit with exceptional focus capabilities. The inclusion of depth cameras in the payload enables quantification of indications found within the pipes, providing operators with precise measurements.

Field Testing and Product Refinement:

Through extensive field testing, the Powertrain underwent rigorous evaluations to identify areas for product enhancement. This iterative process allowed the Nexxis team to fine-tune the Powertrain’s performance, addressing any limitations and optimising its efficiency in real-world pipeline environments. The ability to visualise the anomalies detected by the robot, thanks to the depth cameras, enhances Alcoa’s decision-making process and enables proactive maintenance measures.

Achieving Custom Solutions:

One of the notable achievements of the collaboration between Alcoa and Nexxis is the transformation from relying on available market equipment to manufacturing customised solutions. The Nexxis team’s enthusiasm, combined with their commitment to delivering tailored technology, has led to the successful deployment of the Powertrain in the pipeline inspection industry. The end product surpassed initial expectations and showcases the potential for future advancements in pipeline inspection and maintenance.

Conclusion:

The Powertrain, developed by Nexxis, represents a significant leap forward in pipeline inspection and maintenance. Its ability to navigate within pipelines, identify potential issues, and provide accurate measurements has revolutionized Alcoa’s approach to pipeline management. The collaboration between Alcoa and Nexxis highlights the power of innovation, technical expertise, and a shared commitment to delivering customised solutions that drive industry progress.

Contact us to find out more about the Powertrain or any of our other Pipeline Crawlers, or request a quote online.