Why the Oil & Gas Industry has Fallen in Love with the Elios 2

The oil & gas industry is proving a lucrative market for drone technology. The pandemic notwithstanding, leads and sales have remained stable and even slightly increased in the years 2019-2021. Advanced technology, such as Flyability’s Elios 2 and Inspector 3.0 software is ideally suited for this challenging industry.

Long shutdowns and the risk to humans are the main reasons that companies are keen to find valid alternative inspection methods. Indeed, many are aiming for a “no human in confined spaces” policy within the next few years.

The following are some of the issues that ariel inspection vehicles can overcome:

- Multiple inspection hazards exist: Regular and reliable asset inspections are crucial, yet the geographical design and location of these make them difficult to carry out. Confined spaced, toxic substances, working at height… These are just some of the challenges that traditional inspections have to overcome.

- Excessive safety equipment is required: The risk to human life during inspections is high. This has always been inadequately approached with the use of safety equipment. These include scaffolding, rope access, breathing apparatus and more. Despite all of this, accidents are still far too commonplace. In addition, such methods are expensive and take time and staff training to use in the appropriate manner.

- High numbers of inspection operatives: In addition to the inspectors themselves, high levels of manpower are needed to set up and dismantle equipment – often taking up to 15 days – and bystanders are needed both on the ground and within the assets during the inspection.

- The closure of assets: To make the environment as safe as possible, procedures to close assets, reducing temperatures and shutting off valves are necessary. These represent considerable expense and loss of revenue.

The Elios 2 Advantage

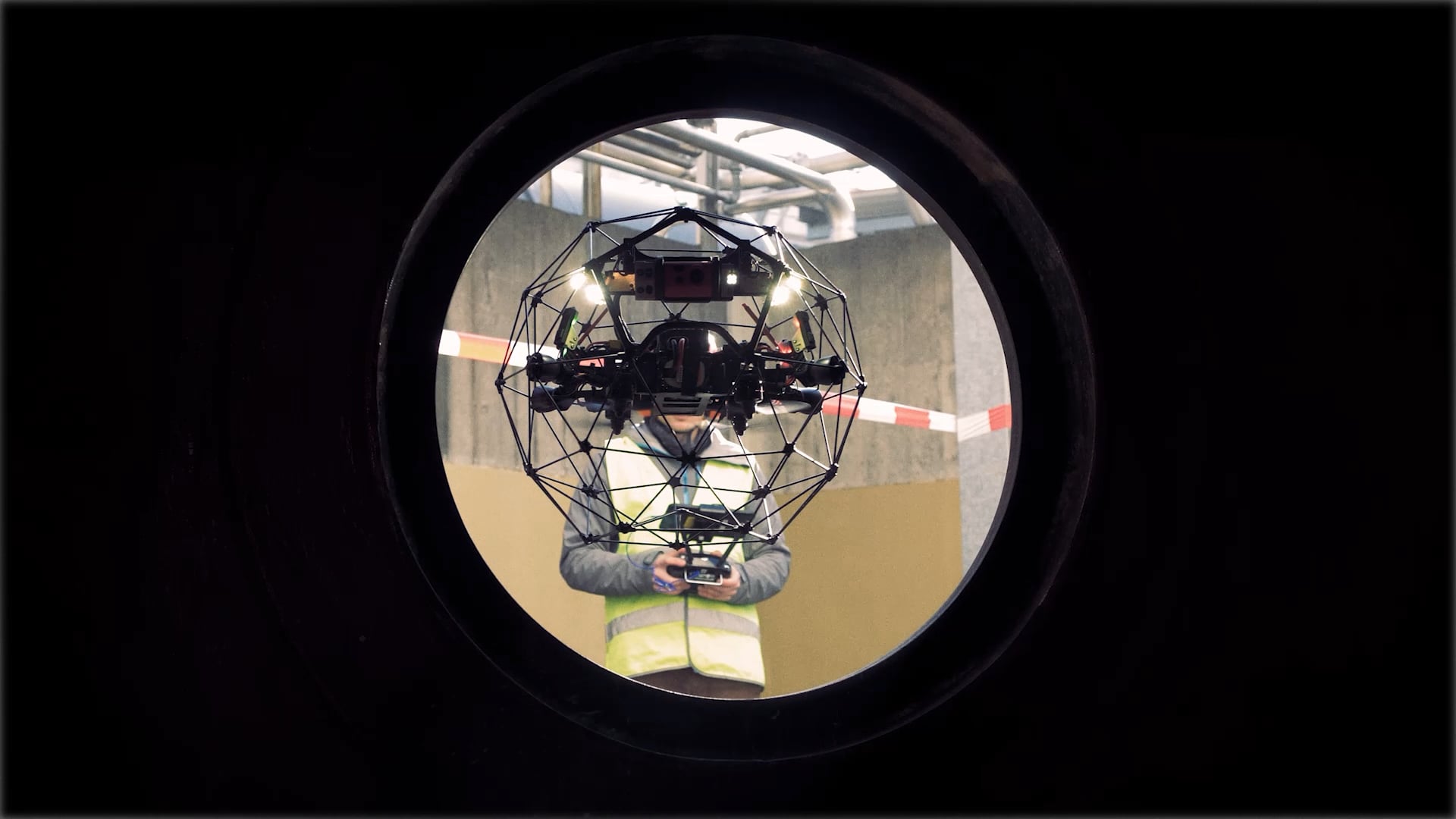

Using the Elios 2 for asset inspections can negate the majority of these issues. In addition, thanks to the data localisation attributes of the Inspector 3.0 software, defects can be accurately pinpointed and the data stored for comparison with future inspections. Other advantages include:

- Enhanced visual data, thanks to HD image capture and high lumen lighting that are far superior to that used by traditional cameras and lights during a manual inspection.

- Exact defect localisation, meaning if repair teams need to carry out work they can accurately enter at the closest point.

- Fast deployment, thanks to removing the need to erect scaffolding and other safety equipment.

- Removing the need for human entry during the inspection.

- Dramatically reducing the downtime of the asset/s. While it’s still necessary to neutralise the assets as drones are not intrinsically safe, the procedure is far easier and quicker than traditional methods. Also, as no human entry is required, any mandatory permits are issued faster.

- Insurance costs are lower, thanks to the reduced risk.

- Far less manpower is needed to carry out the inspection.

- Inspection time is dramatically reduced – often to a period of days or even hours – as opposed to the week or more that’s generally associated with a traditional manual inspection.

All of this means that not only are the inspections of a higher quality and cost less money, but they can also be more frequent. This makes maintenance programming far easier to carry out and an affordable and proactive approach reduces the risk of unplanned work and shutdowns occurring.

Some of the assets that lend themselves well to drone inspection include:

- Storage tanks,

- FCC and cockers

- Offshore rigs, jackup and drilling ships

- Chimneys and smokestacks

Elios 2 Success!

One successful example of how using drone technology for inspections is that of the largest energy company in Turkey. Thanks to the easy access, increased and proactive inspections, the high quality of the data gathered and the accurate data location, the company has successfully reduced the process by an incredible 96%. This considers both the time and monetary savings.

The oil and gas industry is in a volatile period. Not only is there the need to adhere to ever-increasing environmental challenges, but issues, such as the war in Ukraine, are only causing costs to spiral. Companies need to find ways to dramatically reduce costs in order to remain competitive.

Embracing technology, such as the Elios 2, is one such way that mandatory inspection costs can be more affordable. In addition, the enhanced results will have a knock-on effect on maintenance and running costs – something that every organisation must consider in order to remain a true player in today’s market.

Contact us to find out more about the Elios 2 or any of our other custom solutions, or request a quote online.

Carry on reading How Robots Are Shaking up NDT Inspections to find out more.