How a Custom Robotic Crawler Can Benefit Your Operation

Robotic technology is revolutionising the world of asset inspection and NDT. While robot use is becoming more commonplace, those with advanced customisation options– such as robotic crawlers – bring game-changing advantages to early adopters of the technology. Robotic crawlers are used to streamline inspection and NDT tasks of a wide variety of assets. From difficult-to-access pipework to large storage tanks that house internal obstructions, have hard-to-navigate geometry and other accessibility challenges, a regular ‘up-across-and-down’ crawler often isn’t enough.

Enter the era of the custom crawler – platforms with multiple configurations and elements that can be tailored into an almost infinite array of options to suit even the most complex inspection task.

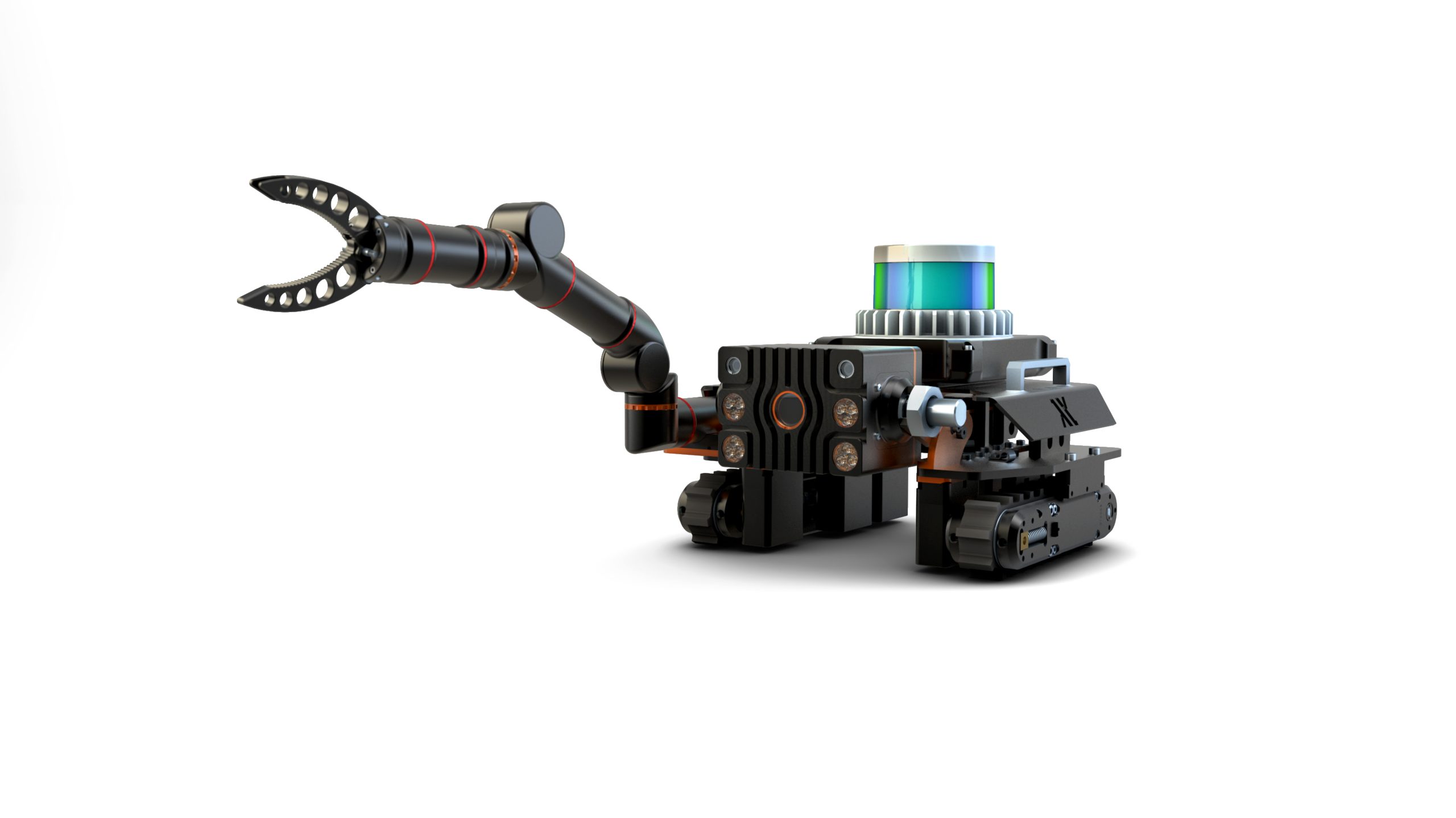

One of the best examples of a customisable robotic crawler on the market today is the Snowcat Crawler. It’s an advanced crawler with a huge array of additional options.

The basic platform comes with impressive credentials, including:

- A 360-degree continuous tilt camera with full 1080p video.

- 10X optical and 12X digital zoom.

- Variable intensity LED lights (spot and floor).

- Parallel laser lines for on-screen size estimation.

Additional extras for bespoke configuration include:

- 100 metres of tether.

- A portable control system with real-time recording of live video, still images and sensor data.

- A rugged waterproof housing.

- Removable camera head – allowing easy viewing any confined space.

- A modular arm for transition and traction challenges.

- The addition of additional NDT capacity, such as sensors to measure coating thickness and resistivity.

While the ability to upscale inspection processes is hugely beneficial from a financial aspect, other tremendously positive ramifications come from using advanced inspection kit, such as the Snowcat.

- Inspection becomes far more accurate: Removing human error from the equation brings increasingly reliable data. This can be stored, tracked and compared with future results. Over time, this leads to a highly predictable analysis of asset MTBF – something that, in turn, brings about the ultimate longevity of a whole range of assets in virtually every industry.

- Inspection times are dramatically reduced: Without the need for humans to carry out high-risk inspection tasks that involve extended preparation and shutdowns, inspections can be carried out far more regularly. A scenario that used to take days or weeks can realistically be minimised to mere hours. This allows maintenance managers to proactively inspect tanks, pipework and other assets, rather than only adhering to the regulatory checks that take place on a (usually) five-year basis.

- Investor and public perception are elevated: Enhanced inspection programs are hugely beneficial in showcasing how an operation is taking control of its environmental responsibilities. As well as this being highly advantageous to how the company is viewed, it also sends a strong message to current and potential employees. Working for a company that takes such steps becomes a draw, helping operations attract the best industry talent available.

Another example of advanced innovation that’s challenging the status quo and moving NDT and inspection to the next level is the soon-to-be-launched PowerTrain. Created specifically for complex pipe inspections, it’s based around a centrally rotating body that spins the payload as it traverses the length of the pipe. This cutting-edge solution is designed for use in multiple applications, including sewer lines, water pipes, drill risers and gas pipes.

This is just one example of how Nexxis works with the latest technology to not only offer Inspection tools on the market to their clients, but to take an active role in the creation, testing and bringing to market advanced designs that truly move inspection tasks to the next generation.

Contact us to find out more about the Snowcat Crawler or any of our other Robotic Crawlers and Tractors, or request a quote online.