Why Magnetic Crawlers are Critical for Interior Tank Surface Inspection

Adequate NDT testing of interior tank surfaces has long been a challenge – especially in vessels that house toxic contents and/or present non-oxygen atmospheres, as well as those that are difficult to access. Historically, testing has required lengthy shutdowns, extensive preparation and high-risk human entry.

While magnetic crawler technology has been around for a long time, it’s only in recent years that they’ve advanced enough to become a truly viable alternative to old-school NDT methods.

Enter (semi) autonomous technology…

Let’s first define exactly what today’s magnetic crawlers are and summarise their capabilities.

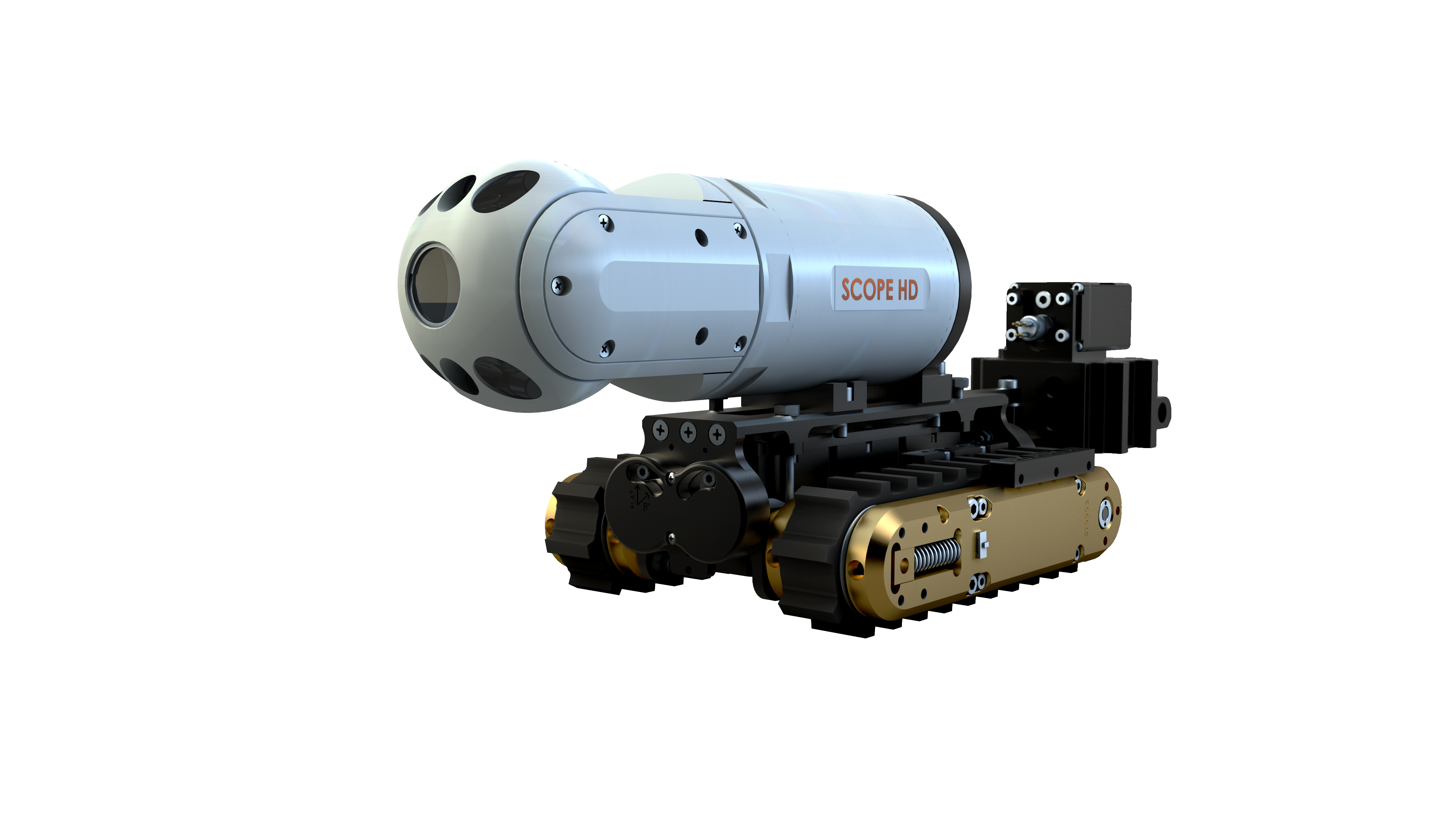

A crawler is a semi-autonomous robot that can be configured to work on various surfaces. In the case of a magnetic model, this is – somewhat obviously – for use on ferrous metals. They’re used to carry out NDT on a variety of industrial structures, from pipework to large tanks and everything in between. Magnetic crawlers adhere to a metal surface with magnets that might be on wheels or tracks, depending on the model. They come in a variety of sizes, from the very small that are used to inspect narrow diameter pipes and awkward areas to those that are larger and for bigger surface areas.

Some crawlers have NDT equipment integrated into their design. Others can be tailored to the individual inspection needs by adding the relevant tooling to carry out the required tests. This will be dependent on the model’s payload – but most can carry pan-tilt-zoom HD cameras and directional lighting to ensure quality images. The best also have the capacity for additional NDT kit, such as laser measurement and profiling systems.

With the option of all of this tech, magnetic crawlers can be programmed and/or remotely operated to carry out a wide variety of testing, including:

- UT testing

- Radiography

- Thermal/infrared

- Visual (via HD images and video)

- Leak testing

As well as removing human entry from the inspection equation and being able to access impossible-to-reach areas, the reasons that magnetic crawlers have become an indispensable element of today’s NDT landscape include:

- They can navigate complex environments: Whether it’s a crowded internal space, hazardous conditions or intricate pathways, a magnetic crawler provides the stable platform necessary to return accurate, uniform test results every time.

- They’re highly precise: The visuals and test results returned from a robot come minus the inaccuracies of human error. Technological precision removes the mistakes of even the best human inspection, bringing accuracy not only to the test that’s being carried out – but also over time, as data of exact points can be compared and thus makes determining asset MTBF a more precise science.

- Cost-effective and highly efficient: Removing the high-cost elements of manual inspection and reducing shutdowns to hours instead of days or weeks reduces testing costs dramatically. Crawlers can also be programmed to target particular areas, follow certain paths and – in the future – will be able to be deployed for wholly autonomous inspections. Today’s crawlers are semi-autonomous – but the days of full testing autonomy are not too far ahead.

As well as all of these advantages, magnetic crawlers fit the future industrial aims of reaching zero environmental impact. Being able to accurately predict how long an asset will last, reduce the risk of catastrophic breakdown to a bare minimum thanks to testing accuracy, speed and ease, as well as eking out asset life to its full extent – rather than replacing (and therefore wasting) materials ‘just in case’ – will play a big part in a fully sustainable future.

There are many magnetic crawlers on the market. One of the most versatile is the Panther Crawler – a semi-autonomous magnetic robot that can be configured in multiple ways to suit an almost infinite variety of inspection requirements. Fitted with a 300-metre tether cable (or longer), high-intensity LED lights, multiple camera options, image enhancement systems and advanced reporting software, Panther is ideally suited for the inspection of interior tanks and pipework with simple and/or complex geometries.

One standout advantage of the Panther is that it can be tailored with a magnetic attachment to allow for vertical ascents and descents, as well as both a parallel configuration or inline for pipework and ducts with smaller diameters (as narrow as 200 mm). With the ability to inspect at speeds of up to 10 metres/minute, a depth rating of 30 metres and a payload of 10.8kg, Panther offers an invaluable inspection medium to a wide variety of industries.

Contact us to find out more about the Panther Crawler or any of our other magnetic crawlers, or request a quote online.