Case Study- Welds Defect Measurement and Inspection Done a Different Way

The Challenge:

A client had a specification to measure the height of the weld seam inside subsea spools.

Included in the client scope was height measurement of the weld, plus the need to inspect the weld for discolouration to identify if any excess heat had been applied to the parent metal.

The Solution:

The Nexxis team demonstrated several different equipment types and brands to ensure image quality was good and the measurement aspects were repeatable.

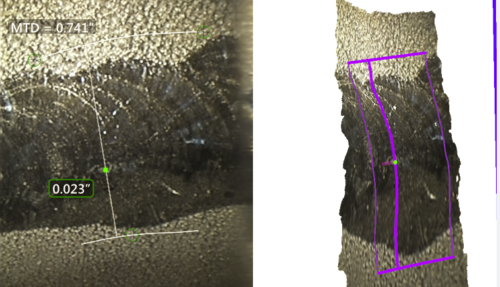

Our solutions team recommended utilising the Mentor iQ borescope technology due to the on-demand 3D Phase and Stereo Measurement options. This allowed us to take advantage of the analysis software combined with extreme image quality for increased Probability of Detection (PoD).

Contact us for a copy of our videoprobe 3D measurement hand book.

As part of our commitment to customer support, the Nexxis technical team provided on the job training to ensure the operators received the most up to date information on the equipment. Training consisted of a theory component and a practical session to ensure competency of the operators.

The training resulted in the participants being able to confidently perform measurements meeting specification to 0.01mm defect as well as confirming weld heights were within tolerance.

The Benefits:

There were two immediate benefits utilising this borescope:

- Measurements possible at any point in the weld seam (360°). A bend and stay tube was also supplied with the borescope which makes the inspection easier. A technique shared from Nexxis on-site experience and lessons learned.

- Utilising a stereo tip will also show weld discoloration. If a closer / clear view is needed, the client could also use a wide angle (120°), near focus tip which was also supplied. The 120° tip provides a clear and a full-screen view of the discoloration. This directly saves time during inspection as the stereo tips do measurement plus and also shows any discolorations at the same time.