Case Study – Creative Problem Solving for Overcoming Temperature Limitations

The HydroFORM phased array corrosion mapper was a complete shift in methodology from traditional UT (Ultrasonic systems) to create quick high-resolution scans with greater flaw characterisation.

The Problem

The HydroFORM UT scanner uses a water column which is fed by a low-pressure irrigation system for enhanced coupling conditions.

The water column is an ingenious design; however, it creates one of the HydroFORM’s greatest limitations which is the surface temperature of the asset being inspected.

When the test piece is hot enough, it causes the water in the water column to bubble, creating a noisy signal as the bubbles disrupt the coupling.

The Solution

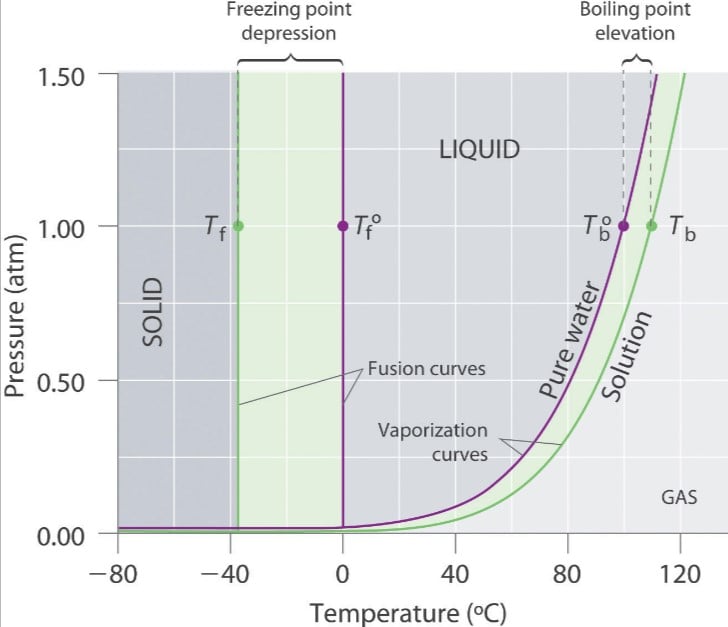

Nexxis was recently part of a trial to test the HydroFORM on higher temperature assets after altering the water mixture to raising the boiling point in the water column.

The boiling point of water was increased by creating a 60/40 glycerine to water solution.

The results were all positive and a successful scan was conducted on the test piece at an elevated temperature of 106°C.

Note:

Please always consult a qualified representative before operating equipment beyond its specified capabilities.