NDT of Pressure Reaction Vessels: A Case Study Into A Vacuum Crawler

Testing tools have advanced dramatically in recent years, yet many organisations have still to embrace the latest technology. Innovative companies, such as Invert Robotics, have honed robotic tech to bring NDT testing solutions that can dramatically cut the time it takes to carry out a task, improve accuracy, safety and, very importantly, save money.

The following looks at one example of how the use of a cutting-edge process offers multiple advantages in all areas.

The Asset

The task in question was that of multiple pressure reaction vessels located in a chemical facility in Germany. Being in Europe, the asset had to be compliant with both German code AD 2000 and the EU directive, EN 13445.

The vessel was Ø2 m in size and made of stainless steel. Previous inspections had been carried out in more traditional ways, each involving extended shutdown, human-driven testing (complete with the associated and accepted errors) and high costs.

The Challenges

The reaction vessels were part of a system that produced over 200 different synthetic resin products. In order to do this, a large number of reaction vessel lines existed – a complex system that was challenging to ensure adequate testing points to comply with regulations.

Testing results had to involve an in-depth internal inspection to ensure every element was in good condition and that any corrosion was within acceptable safety levels. The company was also keen to be able to monitor any issues in order to proactively plan future maintenance when necessary.

They approached Invert Robotics to assess and supply an advanced solution that would speed up the process, increase safety, improve accuracy and reduce costs.

The Solution

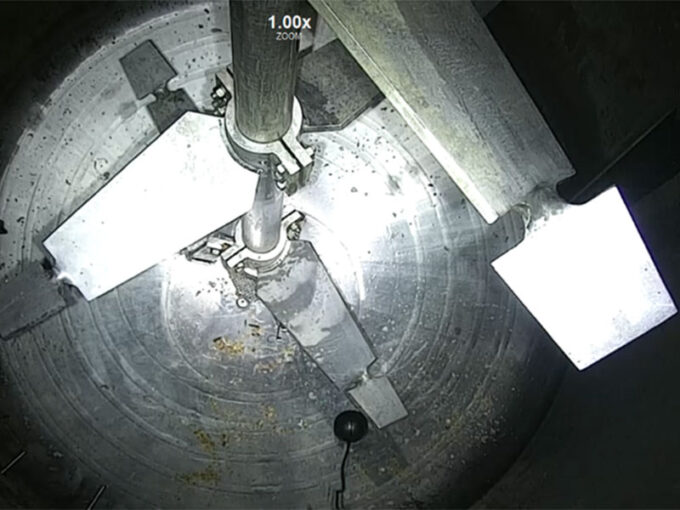

After a bespoke inspection, the proposed solution was to use their customisable robotic crawler that could be equipped with the inspection tools needed for the task. The crawler chosen was the Invert Robotics V1800, a vacuum platform that could easily traverse the non-ferrous, stainless steel surfaces of the pressure reaction vessels.

The crawler was fitted with full HD cameras @ 30fps and state-of-the-art lighting. This, combined with easy manoeuvrability, allowed the operator to quickly gain the necessary data to carry out complete data gathering. This technology allowed the system to easily exceed the necessary requirements in order to comply with the dual legislation. In addition, the time taken to carry out the testing was dramatically reduced, as well as increasing safety, thanks to remote operation.

The first time the technology was used for the task was three years ago. The company was so impressed that they’ve now used this for all subsequent inspections, continually meeting all the requirements necessary to streamline the operation.

Contact us to find out more about the Invert Robotics V1800 or any of our other Robotic Crawlers and Tractors, or request a quote online.