Drone Use Skyrockets as the Cement Industry Embraces Tech

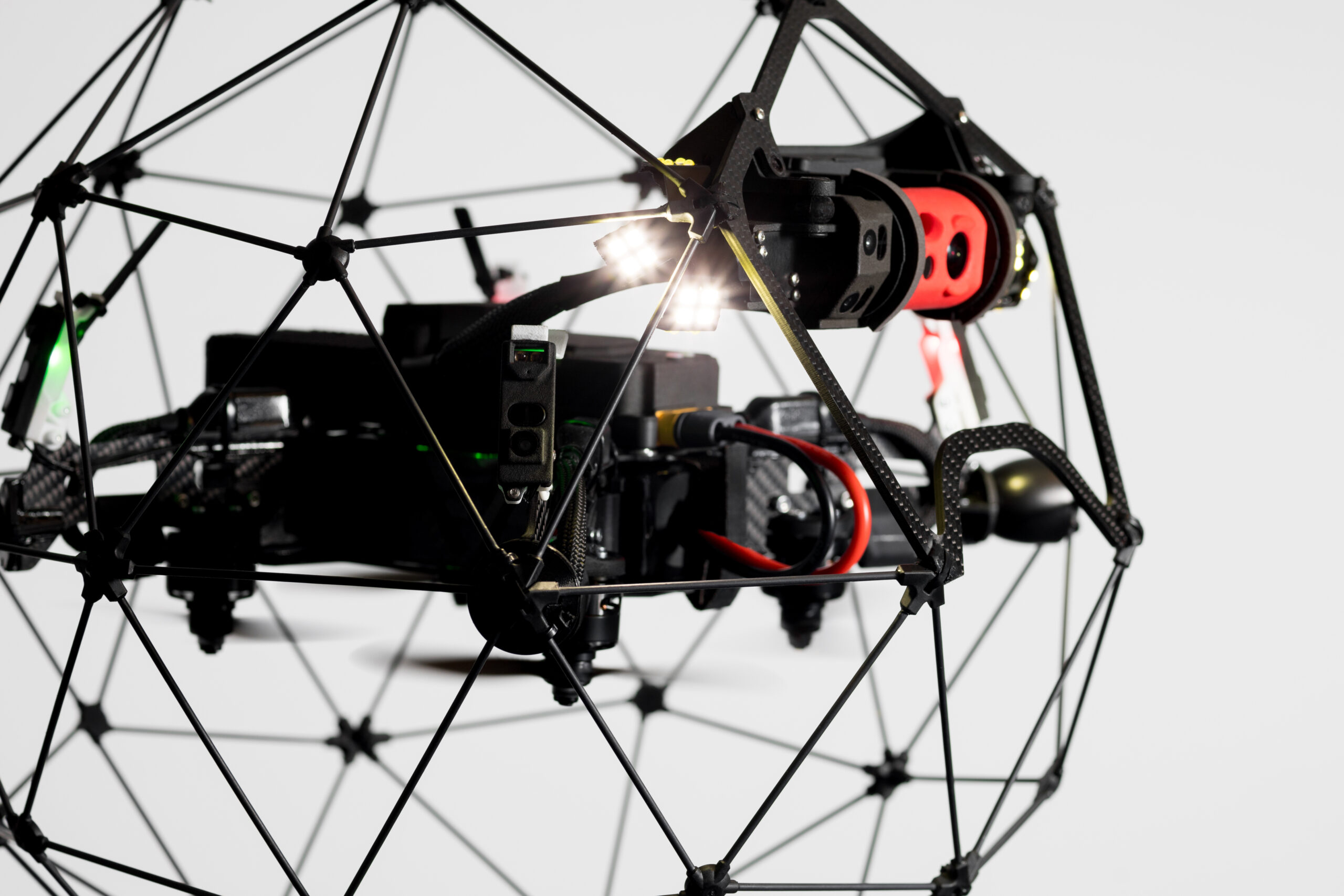

Drones, such as Flyability’s Elios 2 in combination with Inspector 3.0, which is designed for effective indoor navigation, have been well embraced by a variety of industries over recent years.

One area where this is particularly relevant is the cement industry. While it’s true that this growth here has been a little slower than within the fields of oil & gas, power generation, infrastructure and chemicals, 2021 has seen drone sales to cement-related plants increase exponentially.

The reasons for this are a combination of healthy pandemic recovery and a realisation of how advantageous such ariel inspection vehicles can be.

- Cement is one of the most widely used substances on the planet. It’s also extremely hazardous to those who work in close proximity to its airborne particles. Assets, such as silos, kilns, storage units, cyclones and slurry tanks require regular inspection. An indoor drone removes the need for human entry to such locations. A drone can gather inspection data safely, with the operator remaining a safe distance away.

- Traditional inspections require the erection of scaffolding for the inspector to enter the assets, or perhaps rope access to descend from above. Such methods are costly – both in time and expense – not only putting the inspectors at risk but also requiring partial or complete plant shutdown while the prep, inspection and dismantling tasks are carried out. An ariel inspection vehicle completely removes all of these issues.

- Insurance premiums are understandably high, thanks to the risk to human health from inhaled dust and the dangers of working at height and within a confined space. Inspection drones represent a dramatically lower risk and companies can therefore expect an associated reduction in insurance costs.

- A drone, such as the Elios 2, provides inspection data for internal areas that are impossible for human inspectors to reach, such as cyclones. Enhanced data allows for more proactive maintenance, so preventing issues that may well have progressed to failure without having such information.

- Once an area of repair is located, the software of Inspector 3.0 can provide pinpoint accuracy. This makes human intervention to carry out the repair faster, thanks to the engineer knowing exactly where to work.

- The data gathered by Elios 2 and Inspector 3.0 is significantly better than a traditional inspection. This is delivered thanks to HD images, video and bespoke lighting that can’t be matched by the cameras and lights used by human inspectors.

- The ease of drone inspection allows for fast spot checks and an increase in the number of inspections, so reducing the likelihood of unexpected corrosion and asset failure. In turn, this makes maintenance planning more proactive and cost-effective.

Some of the revolutionary advantages the Elios 2 indoor drone brings to the cement industry include:

- Reducing days of inspections down to mere hours

- Reducing the need for manned entry to confined spaces or working at height

- Allowing for more frequent inspections and proactive maintenance programmes

- Precise data localisation leading to faster maintenance and repair tasks

- Increasing safety, helping with employee recruitment and retention, as well as making a concern more attractive to investors and customers

As the many advantages become apparent, the use of innovative indoor drones is becoming more widespread. 2021 saw a leap in the number of drone sales and 2022 is already set to eclipse this.

Has your operation bought into the future yet? If not, can you afford to be left behind? Now is the time to cement the deal and buy into technology – you can be sure your competitors are…

Contact us to find out more about the Elios 2 or any of our other custom solutions, or request a quote online.

Carry on reading Is Proactive NDT Inspection the Key to Great Asset Management? to find out more.