Case Studies: Elios 2 Inspection Drone Changing the Mining Industry

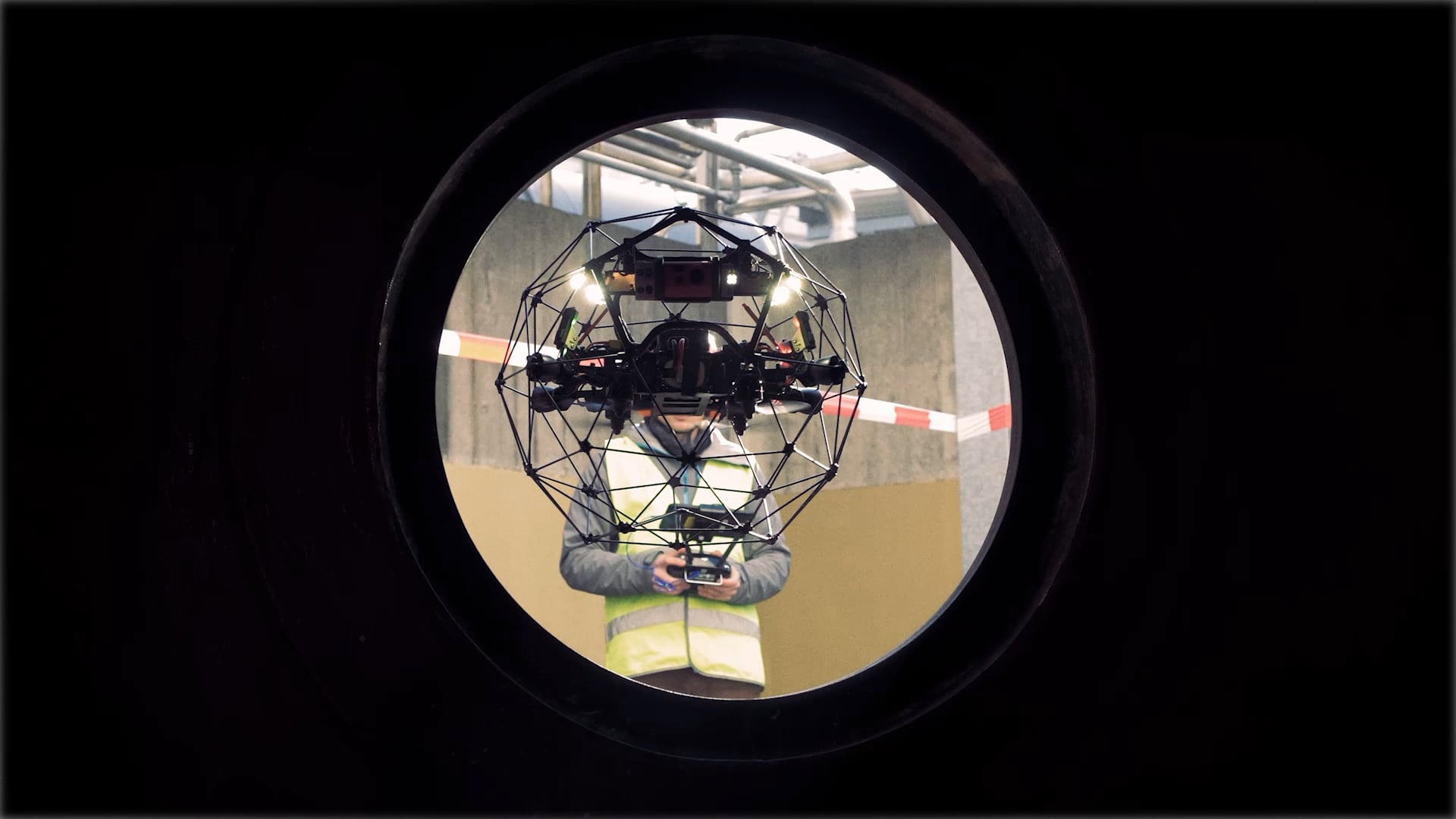

Drones are emerging faster and faster into the minds of the workforce when the discussion of an indoor inspection comes into the discussion. By allowing drones to be used safely inside buildings, it enables industrial companies and inspection professionals to reduce downtime, inspection costs, and risks to workers. The mining industry, in particular, have been using drones to ensure they receive accurate and reliable inspection results while enhancing the safety of the workforce. The new Elios 2 Inspection Drone by Flyability provides these results and more:

Improved Safety: Keep your workforce safe

Every day workers put their lives at risk by inspecting complex and dangerous environments. By utilising drones for your next inspection, and keep humans out of harm’s way. Drones are especially useful for mapping inaccessible or difficult to reach areas.

Extreme Efficiency: Get the job done fast

Work smarter and more efficiently with the Elios 2 Inspection Drone. Increase your productivity through the fast

Easy for anyone to use or operate with GPS-free stabilization

Collision tolerant and distance lock

Cost Savings: Your cost-effective solution

Reduce your costs

More detailed and accurate data: Helping with decision making

When it comes to a visual inspection, data is what matters. With drones, we now gather more information about mine sites than ever before. Quick and accurate inspections from the thermal and 4K camera, 12 megapixels and video recording give high detailed imaging.

Collecting and processing data; Fully navigable and fully measurable in 3D.

Case Studies

Tank Inspections

Tanks are usually inspected every 5 to 10 years depending on local regulations. Typically, the inspections are made to check the integrity of the fabric and rafters, as well as avoid leaks or spills. For these inspections, the tanks must be emptied, flushed, and left to air out for several days. Once they are clean, workers must enter the dark and confined space. Scaffolding then needs to be erected throughout so that every inch can be visually inspected. This process is lengthy and can be dangerous; OSHA estimates that there are 10,000 scaffolding accidents each year. By using the Elios, TAU AG, an asset manager in charge of a tank farm in Switzerland for BP and Avia oil companies, was able to reduce inspection time of their tanks to two hours and avoided the cost of scaffolding (up to USD 200K).

Elios allows employers to keep their workers out of harm’s way. Because these inspections are cheaper, safer, and quicker, they can also be done more frequently. Novozym, for example, led an unplanned inspection using the Elios and discovered several issues with fermenter tanks they wouldn’t have discovered until an incident occurred or until a later planned inspection. With a UAS, inspecting the rafters, the integrity of the fabric, the junctions between the walls and the roof, the welding, and the fitting pipes, inspections can be done quickly, safely, and efficiently. There are also emergency cases where tanks must be inspected. For example, a large asset owner required a UAS inspection after the roof of a tank exploded due to the tank being overfilled. There was a high likelihood that the roof would collapse, making human entry extremely dangerous. By deploying a UAS, the asset owner was able to inspect the entire roof in half a day and without having to set up scaffolding in this hazardous environment.

FCCs, cokers, and production units

FCCs, cokers, and production units are the hearts of many plants: this is where crude products are transformed. Because they are so critical to operations, they must be in perfect condition to ensure continuous production. Once again, robots enable inspections of these assets without having to work in confined spaces, all the while saving hundreds of thousands of dollars in scaffolding. As we distribute more and more indoor UAS into these assets, we notice that companies are shifting to preventive inspections, enabling them, for example, to notice faults in equipment well before an incident, thus saving significant and costly downtime as well as ensuring continuously efficient production.

Chimneys and Stacks

Chimneys and stacks Inspecting stacks can be particularly difficult and time-consuming. In some cases, inspectors must both use cranes and scaffolding to get a full visual on the various points of interest. The time to inspect a stack with a UAS such as the Elios is drastically reduced from days to hours.

Pressure Vessels

Pressure vessels hold gas or liquids at high pressure and must be inspected and maintained often because of the risk presented to workers in case of leaks or explosions. Pressure vessels are difficult to inspect because they are confined spaces; lengthy training and cost are linked to maintaining them. Because of their design, pressure vessels are difficult to inspect with crawlers or unprotected UAS. The Elios, however, can easily navigate its way through the asset and obtain detailed visuals with its powerful lighting system.

Boilers

Because of the size, they can reach, boilers are difficult and dangerous to inspect. Conducting an inspection can require extensive scaffolding and lengthy downtime. ASME’s committee on UAS inspections estimates that the total cost of a boiler inspection can easily reach USD 140K. With the Elios, plants can inspect the boiler easily and without need for scaffolding. While other UAS can inspect the larger areas of the boiler, none can be manoeuvred between the narrow spaces of the sheets besides the Elios.

Other use cases

There are essentially as many use cases for UAS as there are difficult or dangerous places to inspect. A few notable other uses for which the Elios is used includes:

- Pipe inspections

- Jack-up rigs inspection

- Ballast inspections of offshore rigs

- Production units and ballast inspections of FPSOs

Robotic technology is changing the way in which we work as drones are capable of delivering extended capabilities through gathering mass data collection, providing more time for us to interpret this data and help aid decision making. Elios 2 Inspection Drone is providing the mining industry solutions to operational efficiency, reduction of POB, increased safety and reduced costs. Improve your next inspection with Elios 2 Inspection Drone.