6 Steps You Need For Deploying Robots

The case for robots is unequivocal. From remote location activities to unlimited real-time data access, increased worker safety right through an increased ROI, those who’re embracing the era of the automaton are poised to dramatically boost their baseline profits.

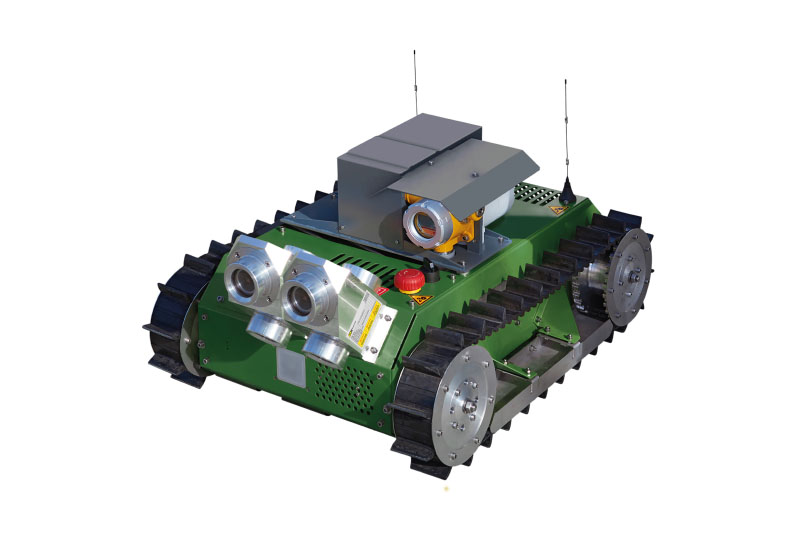

When it comes to the deployment of agile mobile robots, the benefits are multiple. Such advanced tech can go anywhere a person can go and, using sensors and data monitoring equipment, provide immediate insight into exactly what is occurring in real-time. They can also remove many of the repetitive, dirty or dangerous tasks that are currently carried out by humans, leaving workers to get on with more complex tasks that better suit their skills.

The following outlines a 6-step blueprint for robotic deployment that can be used in any field to take full advantage of this must-have technology.

Step 1: Build an executive level experienced team: The implementation of any new technology is only as good as the team that plans it. Not only does expertise ensure that the right deployment plan is put into place, but that there’s the right skillset to integrate a strategy that best suits the business. Board-backed execution is important to ensure everyone within the company is brought on board, from the very top down to those who are boots on the ground.

Step 2: Create a solid hypothesis: The team should formulate a hypothesis as to how agile mobile robots will best benefit the organisation. This can be done in a variety of ways but should include full investigation at every level as to how automation could take over tasks that are dull, dangerous or dirty. Both direct and indirect ROI should be considered, and this will help to prioritise development.

Step 3: Set up concept tests: Testing is a vital step and can take many guises. Some can be done on paper; others require the building of prototypes and test site evaluation. With the latter, it’s important to keep costs in check. Would a ready-made integration suffice for the testing process or is it necessary to develop an individual model? Whichever is the case, set up a range of proof-of-concept experiments for the unit to demonstrate, starting with the easiest first. This would usually be basic mobility, followed by navigation, necessary daily adaptations and the ability to coexist with all other ongoing site activities.

Step 4: Build your prototype: Now you’ve discovered that an agile robot is a feasible option, the excitement begins to build. Creating a custom prototype is the next step, yet it’s still possible to do this in a cost-effective manner by using a variety of off-the-shelf automaton options. The expertise will come from the team’s ability to develop and install code that will integrate with the platform. Site-specific needs can be addressed through software, electronics and a suitable mount.

Step 5: On-site testing: Now you have the prototype it’s time to test the robot’s abilities in-situ. The core function of an automaton is data-collection, so the following are some of the steps that need to be determined:

- Can the robot handle the conditions on-site, navigate obstacles and adapt to any changing conditions?

- Can it collect the necessary data in the required locations? Can this be done consistently?

- Can it safely coexist with other onsite activities?

- How do the site operators best use the collected data?

Step 6: Run real-world pilot programs: This step is designed to show how the robot integrates in real-time and the value that it can add to the site. Bringing the unit to the location and running pilot programs concurrently with regular site activities allows analysis of the positive impact the robot has on daily function and ROI. This final step shouldn’t be rushed. Plenty of time should be allowed to gather feedback from operators and stake holders. Only once this has been received and considered will it be possible to determine the value of deploying robotics in that location.

Whatever form an organisation’s robotic implementation takes, following this blueprint will ensure that full consideration is given to every aspect of automation before a decision is taken to extend and implement throughout the company.

Equipment provider, Nexxis, is dedicated to the provision of semi-automated and automated technology to a variety of industries, including mining, oil & gas, petrochemicals and infrastructure. At the forefront of the technological revolution, Nexxis implements an approach that works with companies to create the solution for equipment procurement that suits them.

Discover more about our full range of robotic inspection equipment or contact us today for a no-obligation chat.