Power Corp. Save Big by bringing Alignment in-house

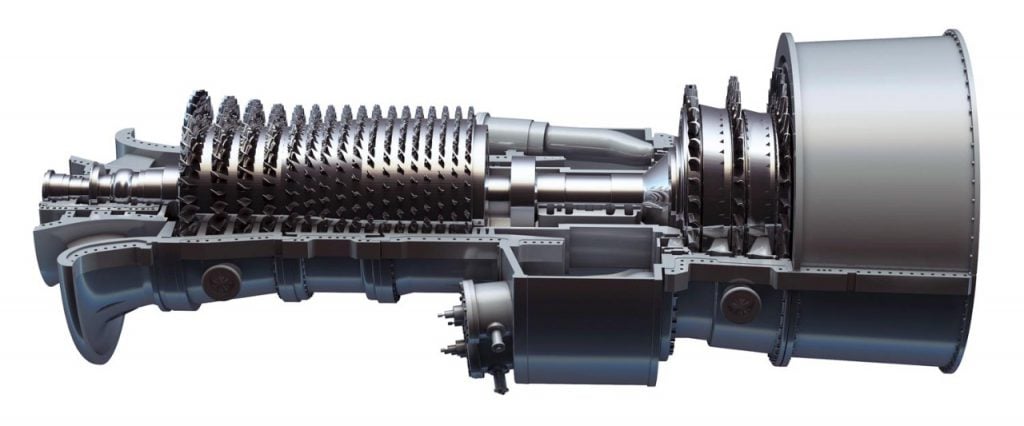

At a power plant in Keratea/Lavrion, Power Corp experienced problems with their GT42 9E gas turbine. The exhaust outlet was too high and caused damage to the middle layer. This had resulted in extended wear on the turbine shaft and bearings, which caused vibration, heat and energy loss. Hundreds of this type of turbine are installed worldwide. Apparently this phenomenon was not unique, it had appeared elsewhere, on the same model types of turbines.

Experienced maintenance engineers

After guidance by the Greek distributor of Easy-Laser®, Metrica AE, PPC decided to buy an E960-B Turbine alignment system and an E710 Shaft alignment system. Using these systems the experienced Maintenance Supervisor Tsioumas Spyridon and his colleagues, maintenance engineers Theocharopoulos George and Pappas Thomas, could control the service and maintenance completely and reduce down-time and costly repairs.

From Easy-Laser AB’s side, Prosper Chekroun, Application Expert, travelled to Greece to hold training for the employees of PPC. Within a time period of one week, they have trained, measured, aligned and re-measured the turbine. A very short time compared to previous service done by other external companies, and from now on they will also save money on the service jobs as they can do them by themselves whenever it is needed.

Live adjustment values made it easy

The turbine was closed, top-on. With special designed brackets for this type of measurement it was easy to define the geometric condition of the gas turbine, make the necessary adjustment to achieve alignment and then re-measure to verify and certify that the alignment was successful and within manufacturer tolerances. The Easy-Laser® display unit made it possible to see the turbine diapraghm movement live, making the adjustment job easier. The personnel knew exactly when to stop moving the diapraghm.

The middle layer becomes very worn, the rotor pressed upwards and starts to gnaw in the white metal.

Turbine to generator shaft alignment

After the completion of gas turbine cells alignment, the shaft of the turbine should be aligned with the generator shaft. For this task they used Easy-Laser® E710 in order to perform the alignment. The system can use thermal compensation values and also as many generator foot pairs as needed. The application offers live monitoring of the movements performed while adjusting the movable engine. The process was successful and was also performed on another unit (engine-pump) on the PPC premises.

All in all, a satisfied customer, and a well-functioning gas turbine.

*Case study originally created by Silje Langhelle