Next Generation Crawlers Solve Nuclear Inspection Challenge

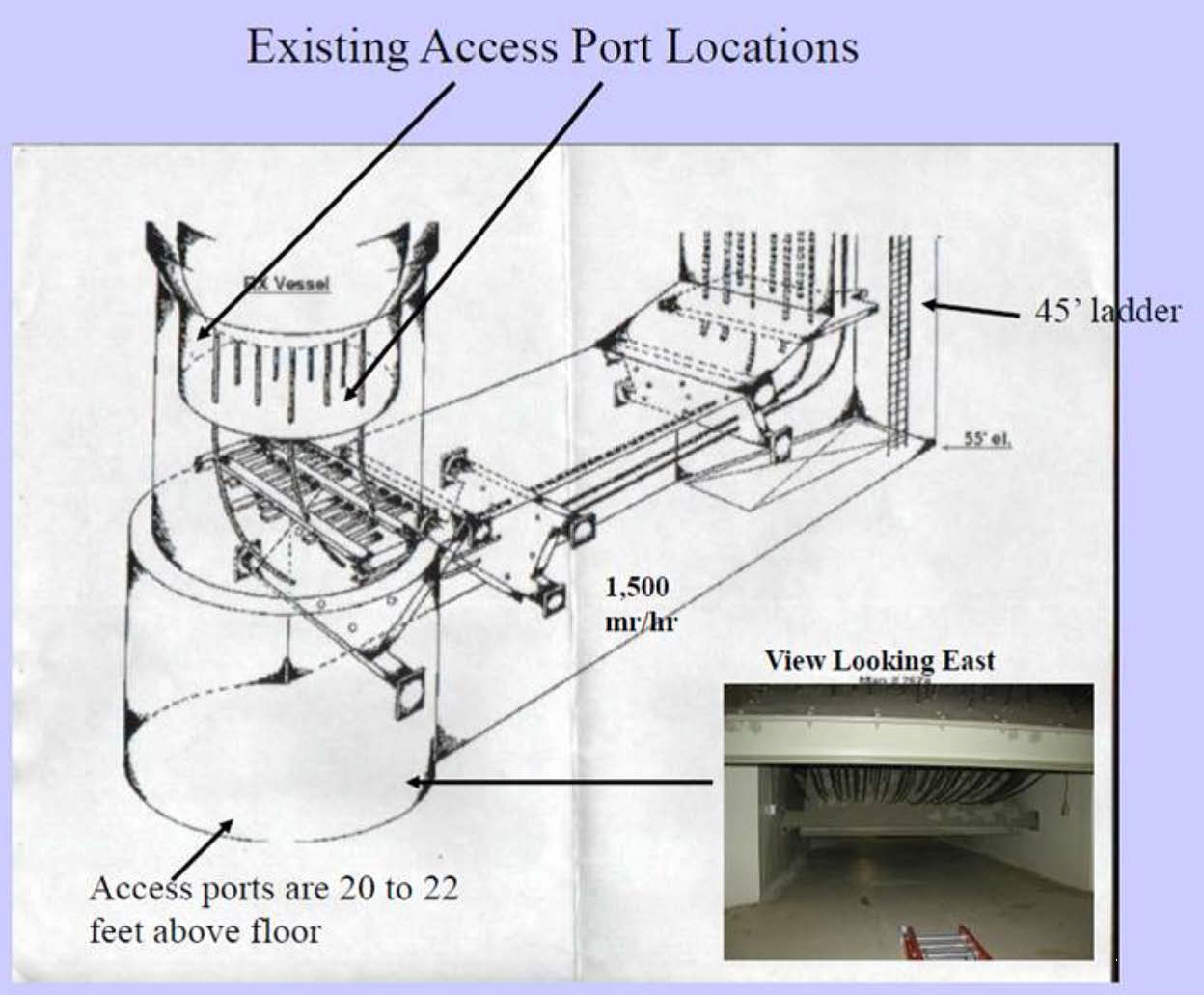

Nuclear plants present significant and complex challenges when it comes to the visual inspection of components.

Space and access constraints are considerable and the hazardous nature of the operation compounds the challenge, plus there are ongoing operational considerations such as cost management, maintenance requirements etc.

The following case study involving the Palo Verde Nuclear Generating Station in Arizona, the largest power plant in the United States by net generation*, illustrates how nuclear plants can overcome these inspection challenges.

The nuclear plant generates around 35 percent of Arizona’s electrical power and serves around four million people, so reliable and consistent operation is paramount.

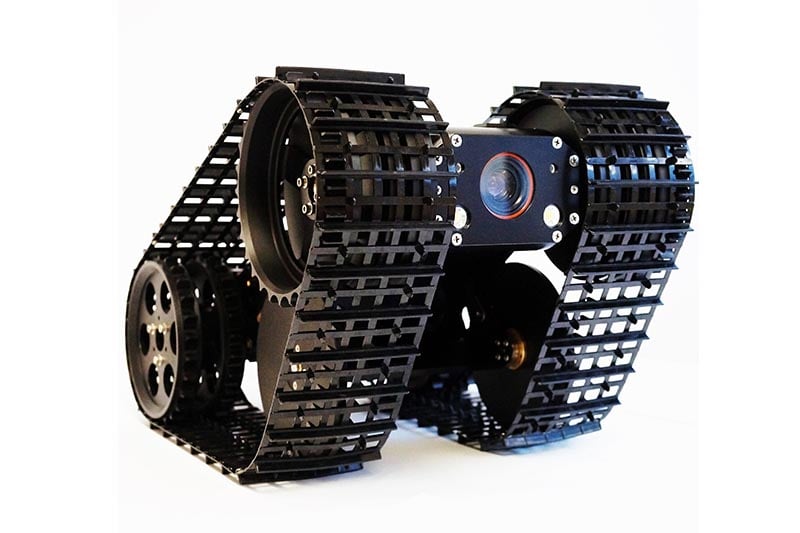

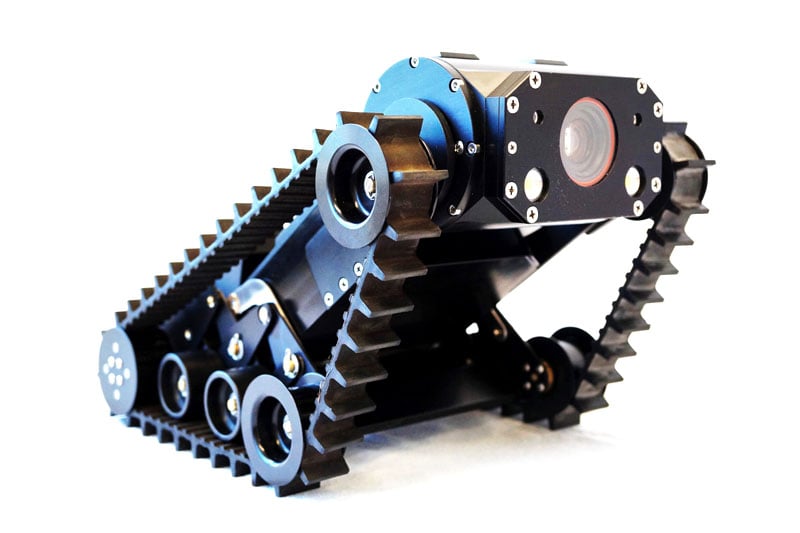

The plant turned to state-of-the art remotely operated robotic systems comprising crawlers and cameras from CrystalCam Imaging Inc to provide visuals of its in-core chase – a very high radiation area which is not designated for normal human occupancy. Together with their high-performance camera attachments, the intuitive Delta Extreme and Delta Micro crawlers were able to provide technicians with clear visual and audio contact using the colour zoom feature with optional bi-directional audio.

Key to the ongoing success of these products is that they have enabled inspections to be carried out while the plant continued with its regular scheduled activities, with little or no maintenance required to keep the devices operating optimally. Importantly, whilst a radiation protection officer has to be in control of the area when it’s being occupied, these devices are specially designed and constructed to be radiation-tolerant.

The Delta Extreme crawler can travel up to 27 metres per minute whilst the more compact Delta Micro travels five metres per minute. The Delta Extreme utilises plastic belts whilst the Delta Micro uses rubber ones, with both models offering 10X optical and 4X digital zoom with optional bi-directional audio. Both are depth-rated to 30 metres.

|

|

| Delta Extreme Crawler | Delta Micro Crawler |

The Delta Extreme and Micro are exceptionally portable, with the whole system fitting into a backpack and deployed and operated with ease by one person. Although compact, (the Extreme has dimensions of 28cm x 43cm x 15cm whilst the Micro is 22cm x 43cm x 11cm), the ‘shape-changing’ capabilities of these vehicles mean they can comfortably navigate tight spaces and manoeuvre over objects and around obstacles.

Whilst nuclear plants have used remote-controlled devices for inspection for many years, new generation equipment like the Delta crawlers and the high-performance cameras with high magnification capabilities have optimised the benefits even further. The equipment isn’t cheap, but their peak performance in hostile environments, superior quality viewing, reduced operator exposure to hazardous environments, reduced maintenance costs, rapid deployment and versatility make them a worthwhile investment.

For more information on these remote-controlled crawlers and camera systems or any other remote visual inspection or non-destructive testing equipment, get in touch with us. As a leading Australian-owned technical equipment solutions provider, we will use our extensive experience and industry knowledge to customise the most economical and flexible solution for your unique inspection requirements.

* Source Wikipedia