Indoor Drones: Removing the Human Risk from Internal Safety Inspections

Inspecting internal assets, such as pressure vessels and chimneys, has long been a necessary evil to be risk assessed and implemented by human hands. Injury and even death have, sadly, been associated with such tasks – and this remains true despite the large number of mandatory safety steps that are in place today.

But technology is successfully changing this. Enter the era of the indoor drone…

The Hierarchy of Control

Anyone responsible for health and safety should be aware of the so-called, hierarchy of control. This is where the most effective method for worker safety is to physically remove the hazard (elimination). Second to this is substitution (replace the hazard), followed by engineering controls (isolate people from the hazard), administrative controls (change the way people work) and, lastly – and least effective – providing them with PPE.

By using a drone you hit the highest tier of safety – by eliminating the hazard of human inspection entirely.

Of course, we must accept that it might not currently be possible to utilise a drone in every scenario. But the future of interior inspections means it will no longer be appropriate or necessary for humans to enter such dangerous spaces. Companies are now able to take advantage of drones specifically designed to carry out such tasks

The following looks at the three major advantages this brings.

- Reducing or removing the need for humans to enter a confined space: Death or injury from confined space entry remains far too high. A comprehensive study* carried out in 2017 showed that the fatality rate in confined space work is estimated to be between 0.05 and 0.08 per 100,000 workers. As well as death, injuries – both minor and major – are commonplace, with events occurring due to falls, inhalation of harmful substances, exposure to heat or electricity and collapsing materials. Remove the human from the inspection and these instances will reduce or be eliminated.

- Reduce or remove the need for scaffolding: There are three dangerous elements when it comes to scaffolding: erection, climbing/working on it and dismantling it. Even when harnessed, falls from scaffolding make up around 25% of fatal workplace falls. While not all of these will be related to confined space entry, reducing the need for humans to work with scaffolding will, therefore, increase safety. Of course, repair work is still likely to require the erection of scaffolding, but drones can carry out initial inspections, meaning such frameworks will only need to be used where maintenance work has been defined as necessary.

- Reduce or remove the need for rope access: This may or may not be associated with confined space entry. Nonetheless, drone inspection can negate the need for inspectors to undertake this hazardous activity, once again removing or reducing the associated risks.

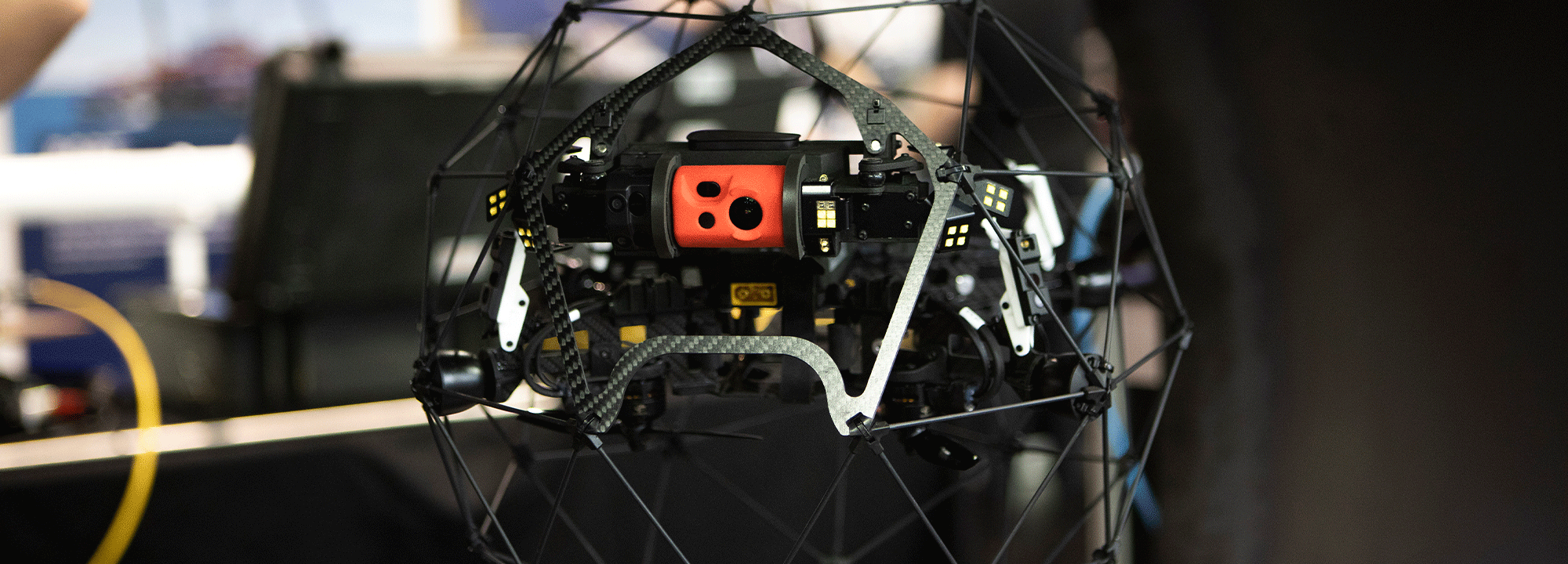

The use of drones within internal assets is increasing, thanks to advances in technology that are overcoming many of the challenges faced in their operation. There are now units available that have integrated and moveable 4K cameras, can fly for extended periods, are simple to navigate and affordable to use.

Advanced as this might be, the tech continues to improve. The benefits are already being reaped by companies taking advantage of such drones, plus sustained investment is being channelled towards further breakthroughs. While today’s drones are confined to visual inspection tasks and are piloted by human operators, the potential for autonomous operation is very much a future goal. This, combined with autonomous robots, sets out a landscape where inspection and maintenance tasks won’t require human intervention whatsoever.

This scenario is, of course, some way in the future. But today’s piloted drones are already removing many of the risks involved to humans when it comes to everyday inspection tasks.

As to how fast autonomous drone and robot operation becomes reality – well, we’ll just have to watch this space.

Contact us to find out more about our range of drones or any of our other custom solutions, or request a quote online.

Carry on reading Is Proactive NDT Inspection the Key to Great Asset Management? to find out more.