Increasing Inspection Capacity With Instrument Hire

Without the ability to hire test and inspection instruments, a leading international aircraft maintenance company wouldn’t be able to respond to periods of high demand as efficiently or as cost-effectively.

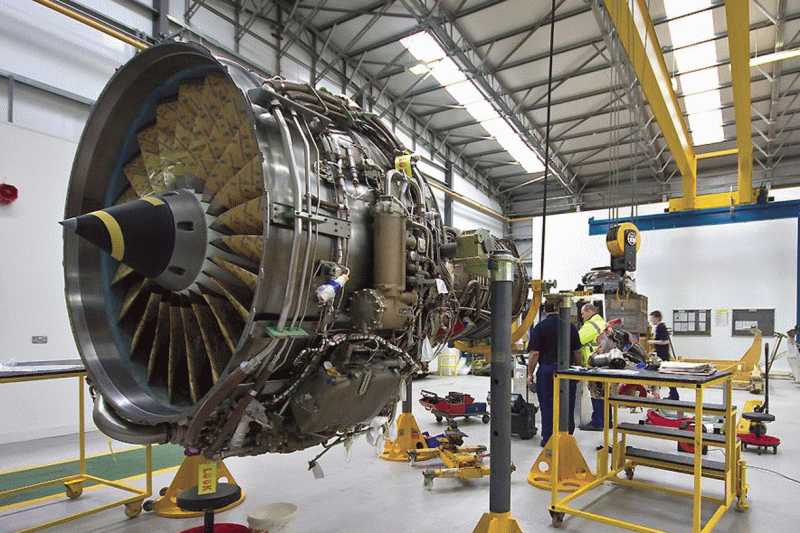

Monarch Aircraft Engineering (MAEL) provides maintenance, repair and overhaul services to airlines in the United Kingdom and internationally and has always supplemented its base stock of test instruments with hired ones. The company has done this for two reasons: firstly to enable it to respond quickly and appropriately to customers’ changing needs and secondly, to enable it to evaluate new devices and technologies without making a significant capital investment upfront.

The company keeps its own inventory of instruments which are used on a regular basis, but then supplements that stock with additional rental equipment as and when required. At all times, however, the test and inspection equipment has to be of a standard that enables technicians to deliver consistently accurate and reliable results. The quality of MAEL’s service is only as good as the quality of its testing equipment, which brings the credentials of the technical equipment supplier into sharp focus.

Reliability of equipment supplier

As with any operation that uses inspection and test equipment to ensure the dependability, efficiency, safety, quality and profitability of their equipment and processes, MAEL relies on a close working relationship with its equipment supplier. Instruments need to be delivered quickly and have to be correctly configured so that MAEL can comply with all regulatory requirements and enable their clients to optimally manage any operational impact.

The nature of the aviation industry requires fast and flexible responses to inspection needs – and quality and safety are paramount.

In MAEL’s experience, having a good working relationship with an experienced technical equipment supplier enables them to respond quickly, efficiently and appropriately in periods of high demand by renting instruments at short notice to meet short-term requirements. The company does not need to maintain its own tooling inventory which has the capability to meet maximum demand – but rather uses equipment hire to fulfil changing requirements for high-quality, accurate inspection and testing at all times.

Reduced capital investment

The smart commercial decision is to use equipment rental to the company’s advantage – accessing resources only as and when required, and not having to make substantial unnecessary capital commitments. Instrumentation capacity can be adjusted according to varying needs (for example, in the aviation industry, the maintenance company can rent the appropriate equipment for non-routine inspections such as after a bird-strike).

Discover the latest models and technologies

Equipment rental also enables organisations to try out new technologies or instruments without making any long-term financial commitment.

For example, borescope technology is constantly advancing and companies can evaluate the latest models by renting them on a short-term basis. Borescopes differ in many different aspects including size, diameter, reporting capabilities, flexibility, magnification, field and depth of view, and instrument hire enables companies to boost their inspection capability on a cost-effective basis and to make informed decisions to improve their own, and their customers’, businesses.

Borescopes are widely used in the aviation industry for non-destructive inspection of the internal structures of components – and serve a vitally important function because they can reach into areas which would otherwise be extremely difficult – if not impossible – to access.

Three examples of where borescopes play a critical role in aircraft inspections are:

- inside the aircraft engine cylinder to look for signs of damage to the pistons, valves or walls;

- in the hot section of a turbine engine (gaining entry through the access plugs or the hole left by the removal of an igniter)

- inside auxiliary power units

For more information on hiring borescopes, contact technical equipment specialists, Nexxis. We are industry leaders in NDT and inspection equipment in Australia and will customise a solution that makes financial sense and which meets your changing requirements and circumstances. All of their equipment is calibrated and ready for immediate use, plus we offer training on all products to ensure optimum performance.