Culvert Inspection Case Study

This case study illustrates the benefits of having a fast, efficient and reliable solution for culvert inspection as well as highlights the financial and operational upside of technical equipment rental.

Amey Plc is contracted by the National Rail in the UK to help keep the country’s railway network running as smoothly as possible – a responsibility which involves the inspection and condition monitoring of over 100 000 assets every year. Pipe and culvert inspection requires checking for cracks, corrosion, debris and blockages.

The company handles 86 contracts for the inspection of culverts passing under railway lines with rail providers and train operating companies including Network Rail, the London Underground and Docklands Light Railway for Transport for London.

The large volume of work and the need for reliable results meant the company had to make careful and considered equipment choices.

Amey rented its first Crystal Cam Delta Extreme robotic system in 2013 and since then, the company has been renting at least one of these every month on a consistent basis. At peak times, they have rented up to four systems in a one-month period.

|

|

|

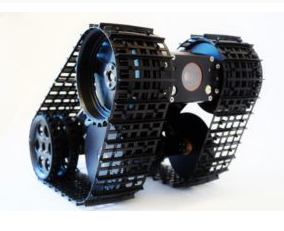

| Lower position | Half raised position | Fully raised position |

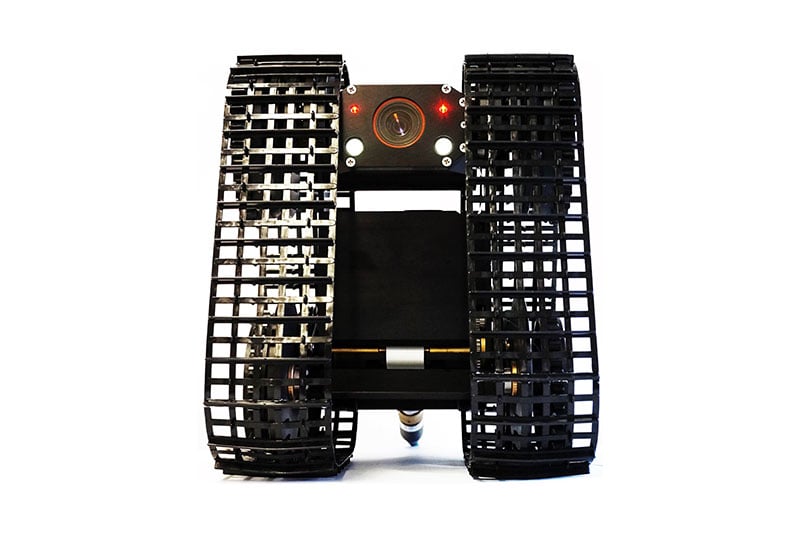

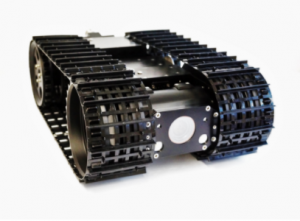

Culvert inspection is one of the common applications for this intuitive, remotely operated robotic system. The Delta Extreme is specially designed for inspection and reconnaissance missions in areas that are unsafe or inaccessible to people such as inside confined spaces and hazardous environments. Its unique shape-changing capabilities enable it to navigate through tight spaces, over objects and around obstacles whilst the specially designed track belts provide optimal traction performance in a wide variety of environments, including underwater to a depth of 30 metres. Fast and flexible, the Delta Extreme can travel at speeds up to 27m a minute and handle temperatures from 0 – 500C.

The compact system (6kgs) is completely portable and fits easily into a backpack. It can be transported, deployed and operated by a single person, with minimal training, which adds a further dimension of convenience and usability to the system.

The vehicles incorporate a high quality tilting zoom camera and LED lighting, with options for on-screen laser lines, bi-directional audio and an image enhancement system.

The Delta Extreme is just one of high quality cameras and imaging products from Crystal Cam Imaging Inc (CCII), which has built a global reputation for quality and solutions-driven innovation. Their industrial products are now available in Australia from Nexxis, a leading technical equipment supplier which shares CCII’s commitment to finding cost-effective, practical and efficient solutions to inspection and non destructive testing challenges.

For more information on the Delta Extreme or any other Crystal Cam product or for an expert opinion on how to solve a particular inspection issue, please contact us.