Crawler Tech Tips: UT Probe Allows MicroMag to Measure Steel Thickness

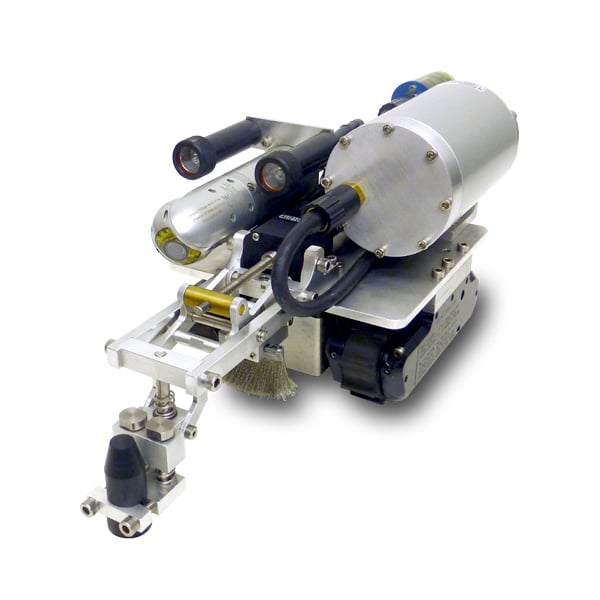

The latest option for the Versatrax 100 MicroMag allows for both non-destructive thickness measurement as well as visual inspection. The mobile robotic inspection vehicle, designed and built by Inuktun Services Ltd. (ISL), can now be customized to include a Cygnus ultrasonic transducer. The UT probe can measure the thickness of steel in pipes, on tank walls and on ship hulls in up to 100ft of water.

Jeff Christopherson, who specializes in technical sales at ISL, says the new MicroMag makes two sets of observations, “one being visual and the other being electronic — the thickness of the steel.”

He outlines the application, “You first identify a suspicious area with the camera, clean the area with the integrated wire brush and then measure the steel using the ultrasonic probe.” The probe algorithm allows for accurate measurement of the metal thickness even if the steel is painted or lined.

“Very often companies coat the inside of a pipe to prevent corrosion of the steel,” he explains. “The Cygnus probe is smart enough to analyze the multiple echoes from a piece of lined steel and factor out the lining thickness.”

The UT system can be used to quantify problems with steel structures resulting from wear, corrosion or other environmental factors.

Christopherson describes the MicroMag as being “solid and built like a tank, yet capable of operating on vertical surfaces or even upside-down. It’s an excellent deployment vehicle for this sensor.”