Case Study: Xtrax-Powered Subsea Custom Crawler

Robotic technology can be advantageous for asset inspection in varied and complex environments, such as hostile and hazardous conditions, confined spaces, limited access, and slippery surfaces.

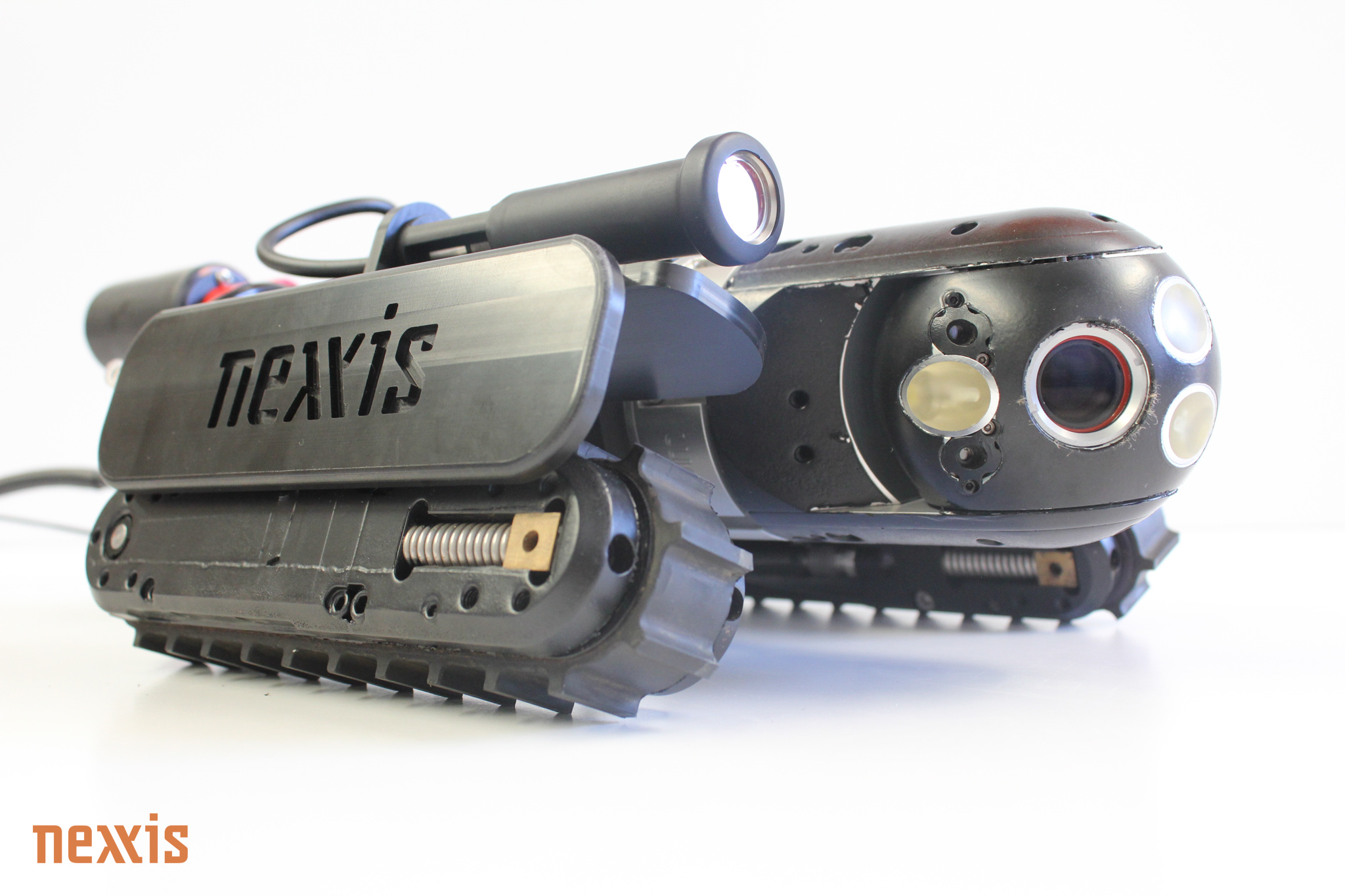

The Xtrax systems built in house by Nexxis, which use small but high-performing LT and Omni crawler modules, are particularly suited for remote applications in confined and hazardous areas that require reliable performance.

Nexxis presents a case study of their custom-made subsea crawler used for inspecting a critical element of an underground section of an SCW network that needed to be inspected to identify any cracking within the internal surface.

The Challenge

The asset construction was glass-reinforced plastic with an interior epoxy coating. It had multiple branch connections to the main header, each of which are under considerable stress. The operator needed to achieve excellent-quality images to assess any damage to the integrity of the pipework.

The main issues were the high quality of the imaging needed in a submerged environment and the dimensions in which the inspection tool had to work. Access to the pipe system was limited and required the removal of a section of piping through which the inspection tool would be inserted. The diameter of this entry point was only 150mm.

The only equipment available that was up to the task needed a minimum of 200mm to work within. This scenario only had 150mm, so it was immediately apparent that a bespoke solution was needed.

The tool needed to negotiate two vertical sections and have the ability to pause as required in a vertical orientation at the branch connections. The task needed to be carried out urgently, and a window of only four weeks was given from initial enquiry to completion.

Due to risks identified during the inspection and the complexity of the task, it was necessary to include robust contingency plans for deployment and retrieval.

The Solution

Following the initial inspection, Nexxis proposed a custom-made, remotely operated, slimline subsea crawler. Designed by the Nexxis manufacturing team and manufactured in cooperation with SixDe, the crawler was formed from Acetal, a type of plastic so both the crawler and the internal surface of the pipe would have similar hardness values. This meant that if there was any contact between them during the inspection that there was no risk of accidental damage.

The choice of Acetal was also considered as it provided the strength needed to mount the imaging and lighting equipment needed to gain the quality of images required. Its superior mechanical properties allowed for strong magnetic Xtrax Omni, floodlighting and a large optical zoom camera to be fitted. These were essential to provide the high-definition images necessary for an accurate inspection.

Many of these Xtrax-powered crawler systems also have specialised hardware which exerts a downward force on the tracks by pushing against the top of the pipe. This feature stabilises the crawler and enables maximum traction – even to the point where vertical travel is possible.

The system allowed for the necessary vertical orientation and the ability to stop at the branch connections for clear images to be gathered as required.

The Outcome

The high quality of the images collected provided the asset owner with two inspection elements:

- The identification of a few minor damage mechanisms, mainly at points of concentrated stress at the branch connections.

- The collection of multiple data that could be stored and used for future inspections

The customer was highly impressed by the quality of the images achieved – far superior to any that might have been taken by a standard crawler. This was especially relevant as the inspection was carried out in a submerged environment proving that sandy, slippery, icy, slimy, wet, dry or silt-covered surfaces – even some vertical faces – are no match for the Xtrax-powered robotic crawlers.

For OEM clients with precise integration and operational requirements, the tracks can be purchased separately with specific options for interface technologies, power, speed and depth rating.

Discover more about this refreshing approach to robotic inspection or contact us today to see how we can best help your business.