Case Study: The Use of Robotics For Inspection & Maintenance of Process Piping

Process piping is, without a doubt, the most important element in the infrastructure of a processing plant. Such pipes are the means of transport for a variety of contents, including acid, alkaline, hot cold, toxic, pressurised and more. As such, ensuring their integrity is of the utmost importance. and one that currently accounts for a large amount of downtime (and therefore revenue) of a plant.

A failure of a pipe at any level can be catastrophic. Therefore the ability to effectively inspect and maintain them is crucial. Up until recently manual surveillance had been the only option by which to carry this out.

Today there is an alternative solution: that of robotic inspection.

How robotics can overcome inspection and maintenance challenges.

Process piping covers not only those that transport commodities, but also substances used in the generation of power to a processing plant, water and sewage. The elements of piping to be serviced include the pipes themselves and all their workings, such as:

- Fittings and flanges

- Valves

- Elbows, joints and bends

- Pipe bridges and expansion loops

- Pipe support areas

- Pipe racks

Much of this is likely to be in hard to access areas, such as at height, below sea level or even underground. Therefore accurate human inspection has historically been difficult to carry out.

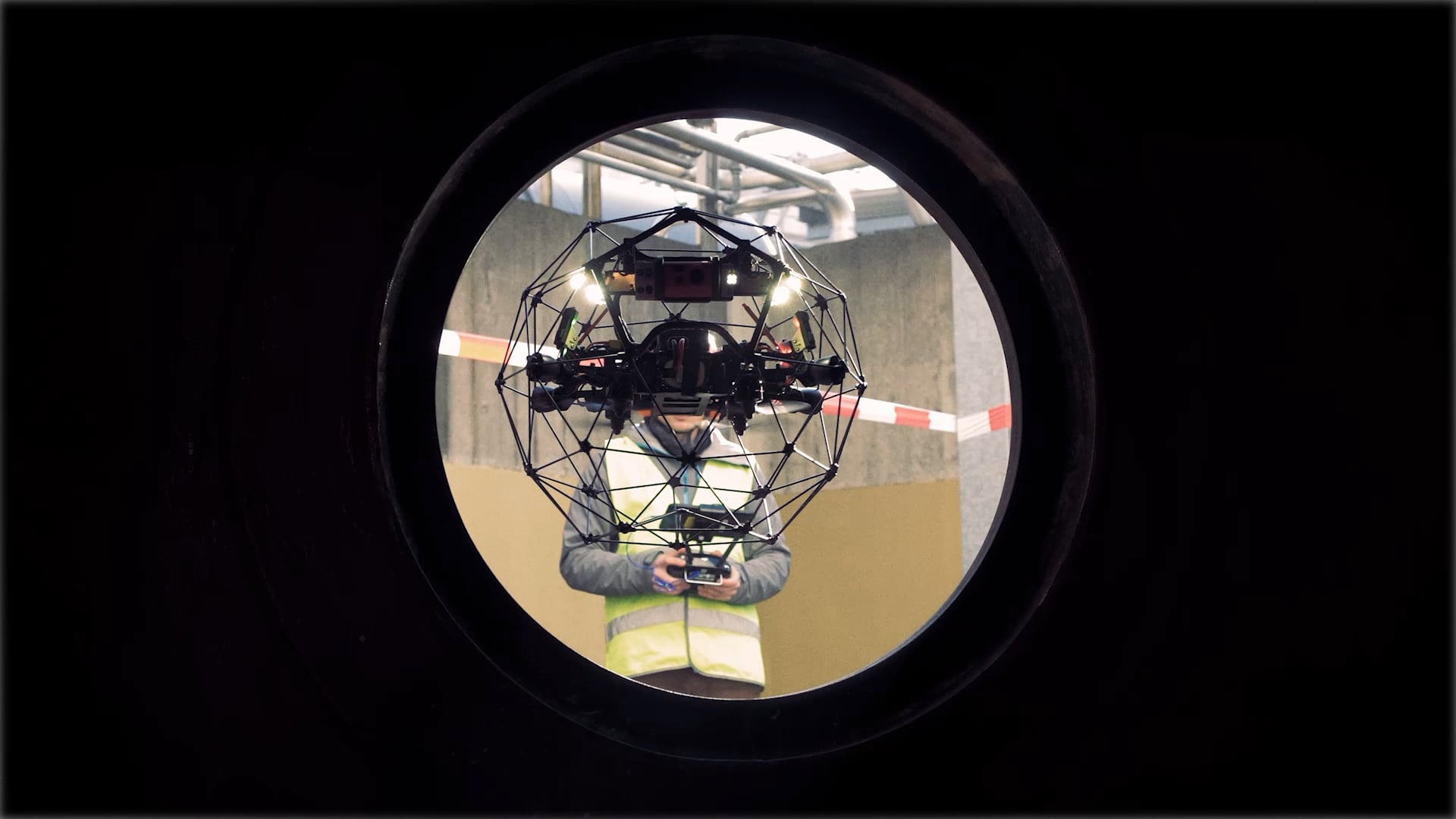

By using robots, drones and unmanned aerial vehicles (UAVs) not only is it far easier to inspect hard to access areas, but it negates the need to ensure a location is safe for a human to approach or enter.

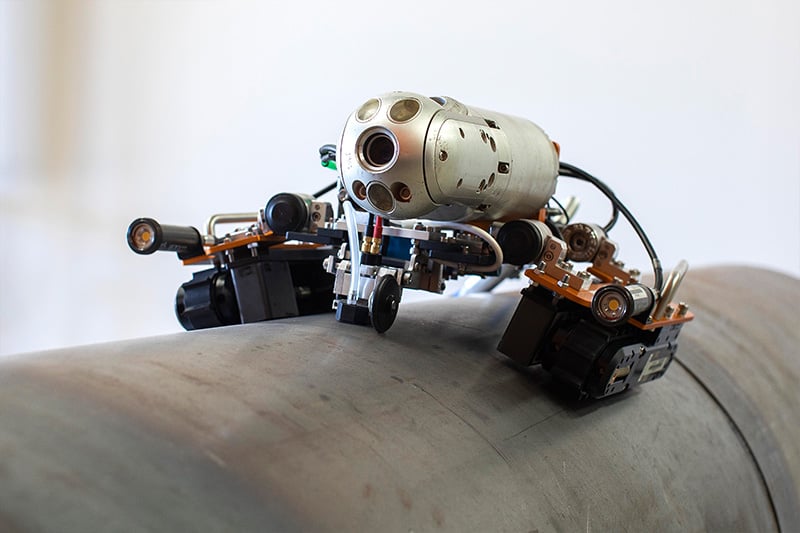

A UAV can be used to quickly assess the exterior of piping at height, and the internal workings can be viewed by a variety of different types of robots, of which crawlers are currently the most popular in use.

Current technology and gaps in capability

However, the use of robotics for inspection and maintenance of process piping is still in its infancy. As it stands, it’s still necessary for pipes to be taken offline for a robot to enter, and technology is not yet advanced enough for seamless movement through all internal obstacles. Nor are robots sufficiently sophisticated to be able to carry out many necessary maintenance tasks.

Challenges still to be overcome at a level whereby they can be brought to market include:

- The ability of a robot to crawl over obstructions in order to allow the sensors that capture data to be close enough to desired locations

- To be able to crawl over insulated pipe (such as that cased in ferro-magnetic or plastic)

- Visual sensors that allow navigation close to obstructions or dense pipe rack

- Autonomous inspection and navigation in a complicated environment

- Intricate maintenance actions, such as mounting a guided wave ring on a pipe or the removal and re-mounting of insulation

- Automatic interpretation of inspection data

However, using robots for process pipe inspection and maintenance is already proving hugely advantageous. To this end, much time, effort and finances are being dedicated to overcoming these challenges.

Robotics are already being successfully utilised in the following scenarios:

- Interior and exterior inspection of small and large diameter pipes

- Those in non-oxygen atmospheres, including subsea

- Inspection of smaller pipes without taking a main out of service

- In-line inspection of unpiggable pipes

Near future scenarios and expectations

The industry is increasingly adopting pipeline transportation as the demand for gas, oil and related products rises on a global scale. According to a 2019 report published by Zion Market Research, the current market for in-pipe inspection robots was valued at approximately 605 million US dollars (as of 2017). This is expected to increase to over 2,450 million by the end of 2026.

The above-mentioned challenges are ones that robotic specialists are keen to overcome. Therefore it’s safe to assume that routine use of humans to carry out the cleaning, inspection and maintenance of process piping will gradually be phased out as we move aside to embrace the new era of robotic delivery.

When considering how such technology could streamline operations it’s vital to work with a supplier that understands the intricacies of the industry. Nexxis follows an innovative approach to the hire and sale of cutting-edge equipment, as their experts know that each scenario is individual to the project. As such they work with their clients to determine dynamic solutions appropriate to the tasks required and that have the ability to evolve along with ongoing operation needs.

To find out how ‘the Nexxis approach’ could revolutionise your operational efficiency, visit nexxis.com or call them on 08 9418 4952