Wind Turbine Alignment in High Winds

Precision alignment of the generator to the gearbox in a wind turbine (the high speed shaft) is critical to proper operation. 60 percent of wind turbine downtime is related to drive train failure: gearbox, generator, main shaft, and their associated bearings. We also know from industry studies that misalignment of rotating machinery is responsible for more than half of all bearing failures. It is for these reasons that shaft alignment checks in a wind turbine should be a very important part of any maintenance program.

Wind turbines start generating power at a wind speed of approximately 3 to 4 m/s (meters per second),

1 m/s equals approximately 2.2 MPH. This is called the cut in speed. Sustained electrical production usually takes place somewhere between 15 to 17 m/s wind speed and the maximum speed a turbine can tolerate is called the cut out speed and is usually about 25 m/s. Between 4 and 8 m/s, you can feel a definite “swaying” of the tower. So, is it always possible to check or perform a shaft alignment on a wind turbine? Actually no.

When performing a precision shaft alignment, it is preferred that there is minimal movement or vibration in the equipment being aligned. In a wind turbine, there is almost always dynamic movement in the nacelle caused by the wind swaying the tower from side to side. In higher winds, the top of the tower can sway several feet from side to side, which can typically be seen in the inclinometer values on a precision laser alignment system. If you can sense the tower swaying then so can the laser alignment system. Fixturlaser Laser Alignment Systems have “filters” the technician can select to compensate for dynamic movement or vibration, however there is an upper wind speed limit for safely performing shaft alignments uptower which will vary depending upon the wind turbine OEM and or the specific wind site.

At a recent Easy Laser training class the technicians performed shaft alignments in two different GE 1.5MW wind turbines. The first turbine was aligned early in the morning in moderate wind speeds of approx. 2-5 m/s, the alignment went smoothly and we completed the alignment in about 45 minutes with excellent alignment results.

The second turbine proved to be challenging. After lunch, the wind had picked up a little but was still acceptable. By the time the team got uptower with all of the tools, equipment, and personnel the wind speed had increased to 10 m/s sustained with gusts up to 15 m/s. There was a significant rocking back and forth of the tower.

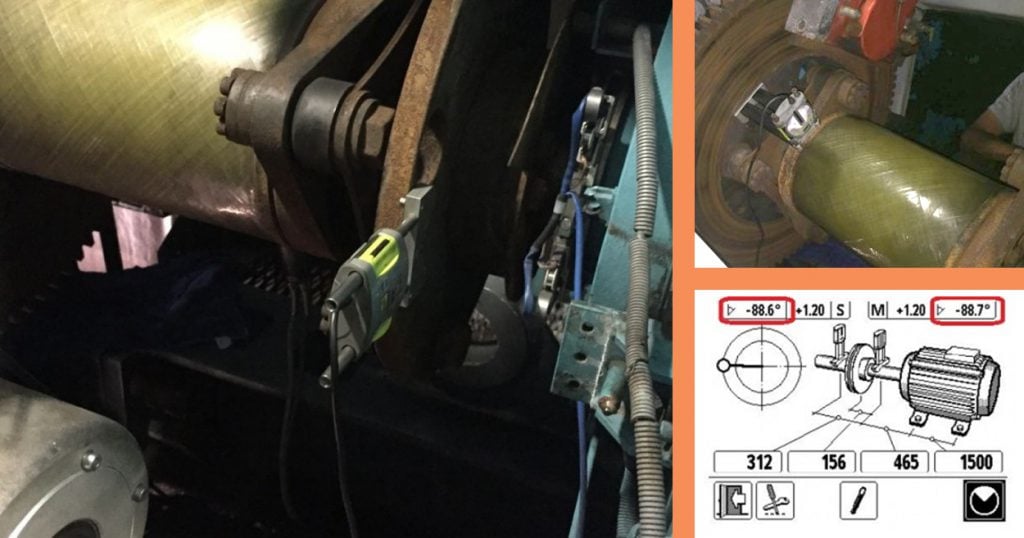

After setting up the Go-Wind Laser Alignment System technicians and students were seeing the dynamic movement created by the high winds.

The inclinometers in each sensor were indicating movement of approximately .5 degrees. This was making things difficult, so the team increased the sampling time to compensate for the high winds and were progressing in the right direction.

As fate would have it, the wind speed continued to increase to 17 m/s sustained and was gusting to 22 m/s which was over the site’s limit to perform a precision shaft alignment.

When dealing with excessive dynamic motion, the position of the machine’s rotational shaft centerlines are changing which can influence the alignment results. Setting “vibration” filters can compensate for this movement, however there is a limit. If at all possible it is best to attempt the high speed shaft alignment in wind turbines when the winds are light.