What If You Could Increase the Uptime Of Your Rotating Equipment?

Laser Shaft Alignment, the life extension plan

The cost of failing to properly align shafts or belts of rotating machinery adds up to much more than physically having to fix damaged machinery.

Misalignment can cause a range of issues from excessive energy consumption, seal and bearing failure, premature breakdown of equipment, damage to couplings, unplanned shutdowns and productivity losses. In fact, as much as 50% of damage to rotating machinery is said to be caused by shaft misalignment – yet it’s relatively simple to fix and prevent (provided you have the right tools of course!).

Laser shaft alignment equipment can maximise your equipment uptime and availability as well as deliver a host of other benefits including reduced energy consumption (some say as much as eight per cent), decreased maintenance costs and improved operating safety.

So how does laser alignment increase the uptime of equipment? Firstly, let’s look at what shaft or belt misalignment means, what the consequences are and then how laser alignment tools can keep equipment in optimum condition.

There are basically two types of shaft misalignment. The first is parallel (or offset) misalignment where the centre lines of both shafts run parallel to each other and the second is angular misalignment, where the shafts run at an angle to each other. Machinery problems can occur as a result of either one of these or a combination of both. Both the horizontal and vertical planes of machinery also need to be correctly aligned in order for optimum performance.

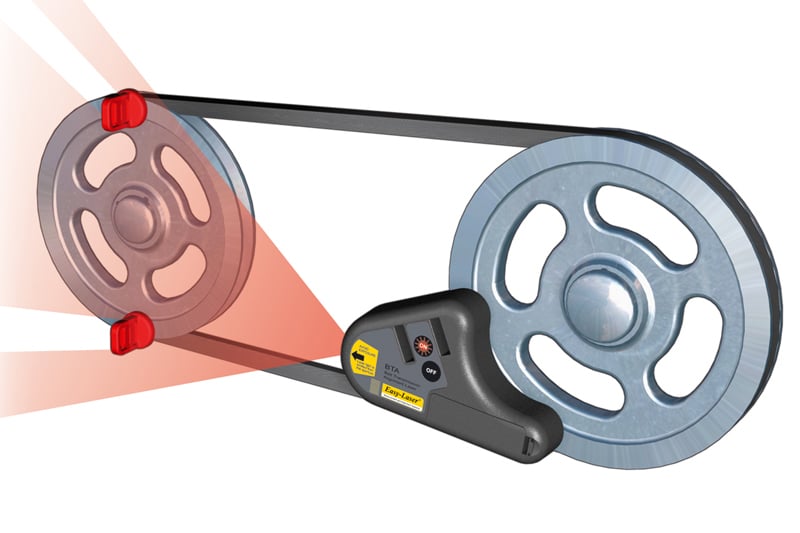

Belt misalignment is another area of concern for operations involving rotating machinery and it is just as important to maintain belts in proper alignment as it is to ensure correct shaft alignment. Aligning belts involves lining up the grooves of the pulleys on which the belt operates, because if they’re out of sync, it can result in the same serious problems as shaft misalignment, including:

- Compromised operating efficiencies

- Increased wear and tear, leading to premature repairs or replacement

- Excessive power consumption

- Increased vibration and noise

- Premature failure of parts

- Excessive leakage of lubricant

- Increased maintenance costs

- Unplanned downtime

All of these issues can be sorted out and prevented through the use of laser alignment technology. Laser alignment is a marked improvement over traditional manual methods and many of the tools on the market today don’t even require any special skills to operate. These devices simplify the whole process of machinery alignment, give machinery a longer life expectancy and keep equipment in optimal condition. Laser alignment is fast, simple, precise and recordable and importantly, laser alignment tools can increase your equipment uptime and availability which will have a direct effect on your bottom-line.

If you’d like to learn more about how laser alignment tools can optimise your machinery and ultimately increase your total outputs, talk to the technical equipment experts at Nexxis. We do more than just supply you with advanced laser equipment tools however. We know how industries operate and we know that your operating landscape changes all the time, so we’ll develop a practical solution that meets your unique needs. View our full range of laser alignment tools for hire, short-term lease or purchase here, and contact us for more details.