Using A Video Borescope For Residue Reduction in Metal Casting

This is the first of six blog posts which discuss the use of video borescopes in metal casting. This one covers video borescopes for inspecting for residue.

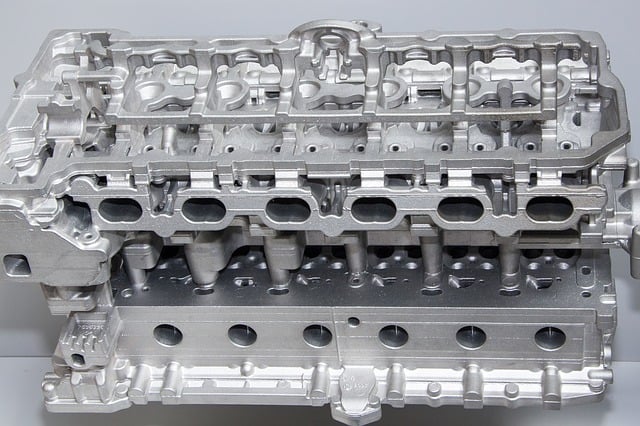

Cast metal components are used in a diversity of applications from art installations to aeroplanes, cars to construction and medicine to machinery.

The highest levels of quality control and absolute precision are required during the casting process (when molten metal is poured into a mould to create a part in a desired shape) to avoid problems further down the track.

Professionals need to make absolutely sure there are no defects or foreign object debris (FOD) which could compromise the performance or operation of the cast metal part – and they rely on visual inspection technologies in order for them to do this.

During the casting process, residue (unwanted material) from alloying and oxidation may be left behind. Any liquid non-metallic components that are left undetected can quickly contaminate liquids flowing through the internal passageways of the cast component and cause major quality or performance problems. Similarly, if the residue produced during pattern pyrolysis is not removed, it can result in casting defects such as folds, blisters and internal pores.

Inspection technicians need the right tools and technologies in order to check for residue and foreign object debris so that casting quality can be improved and the likelihood of problems further down the line substantially reduced, if not eliminated.

We believe that video borescopes are the ideal tool for accurate and reliable inspection of the finer details of the internal passageways and other parts of intricate casted materials. These devices provide an easy-to-use, fast and efficient solution and give both manufacturers and customers the ability to inspect castings for residue and FOD. They also give you the confidence that your cast metal parts are of the highest quality plus they enable visual inspection for any other quality issue, proper fit and wear and tear.

The technology of these devices has advanced rapidly in recent times and many models include innovative features like time and date-stamping and Menu Directed Inspection (MDI) software in multi languages. Your inspectors can document the exact place, date and time that any residue is discovered and can be sure that the high degree of accuracy and reliability of these devices provides peace-of-mind that any residue or FOD has been picked up and dealt with before any significant damage or cost is incurred.

To see if a video borescope can assist your operation to achieve its inspection and quality control goals, get in touch with us.

We are a leading supplier of technical equipment in Australia and we offer an extensive range of advanced video borescopes and other NDT and inspection technologies and products. These are all backed by our many years of industry experience which gives us a unique advantage in delivering practical and flexible technical equipment solutions that are tailormade to suit your unique circumstances.