Ultrasonic Phased Array Testing – An Overview

Ultrasonic phased array testing is a well-established and powerful method of ultrasonic testing that has diverse applications in industrial non destructive testing (NDT).

It is used across a diversity of industries including aerospace, power generation, manufacturing, petrochemical, steel and metal fabrication and petrochemical, primarily for the purposes of weld, casting and forging inspection, the detection of hidden cracks and voids, porosity and thickness testing (particularly in corrosion survey applications) and for analysing other material properties.

Ultrasonic testing has been used in industrial applications since the 1940s but ultrasonic phased array systems really only emerged in the early 1980s.

These early ultrasonic phased array testing systems were large and cumbersome and largely confined to medical applications. When the technology was first introduced as an option for industrial NDT, it was primarily adopted by the nuclear industry where there was a greater appetite and need for cutting-edge technology.

The next chapter in the development of this NDT technique was the introduction of portable, battery-powered instruments which made their debut for industrial use in the 1990s.

This next stage was made possible through the introduction of digital signal processing techniques, inexpensive embedded microprocessors, low power electronic components, surface-mounted board design and portable power sources – all of which paved the way for the rapid evolution of the next generation of phased array equipment leading to the highly specialised and advanced instruments available today.

Systems became more powerful, more efficient and easier to use and because they could be set up electronically with data processing and enhanced analysis capabilities – they became more widely used across the industrial sector.

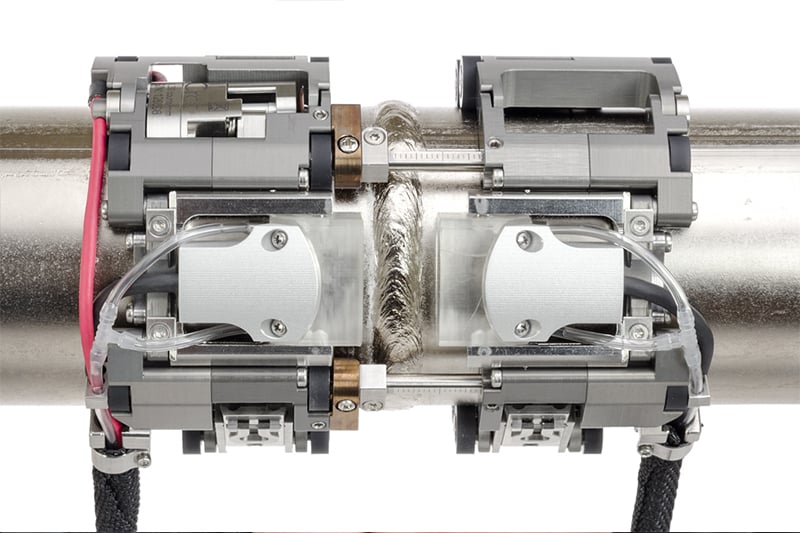

Basically, the technology is based on the principles of wave physics and unlike single-element probes (non-phased array or monolithic probes) which emit a beam in a fixed direction, phased array works by focusing the beam from a probe onto the area under test and combining many angles and focus depths without the transducer assembly needing to be changed. The beam from a phased array probe can be focused and swept electronically without moving the probe – and the multiple elements can be individually pulsed according to timing calculated by a computer to combine with one another and form a single wave front travelling in the desired direction.

The phasing technology allows the beam to be shaped and steered electronically which makes it possible to generate a huge number of different ultrasonic beam profiles from a single assembly.

Advantages of this include:

- Software control and steering of the angle of the beam, the focal distance and the spot size of the beam

- Two and three dimensional views

- High speed electronic scanning

- Multiple angle inspection

- Multiple scans from a single location

- Greater flexibility for inspection of complex geometries

- Optimised focusing

- Motionless high-speed scans from a single transducer position

Today, ultrasonic phased array testing is well-established, safe and powerful and is used widely across a diversity of industries including aerospace, power generation, petrochemical, steel and metal fabrication, oil & gas, general manufacturing and nuclear.

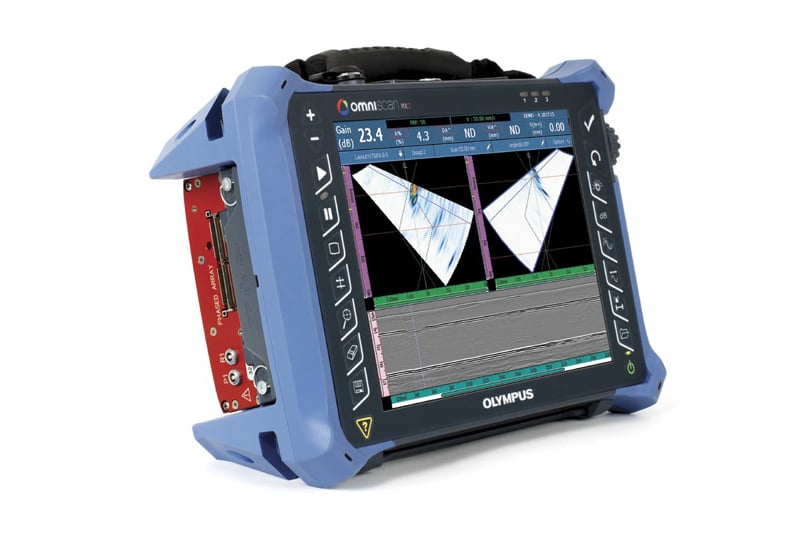

There are many different ultrasonic phased array testing devices on the market offering varying levels of complexity and capability. An experienced supplier of technical equipment will advise on whether this technology is appropriate for your particular situation, which level of capability and functionality is required, which is the best value-for-money solution and how to maximise your investment.

If you’d like to know more about this highly efficient and powerful NDT technology, you should have a chat to the experts at Nexxis. They are an Australian-owned supplier of NDT and remote visual inspection equipment and will make practical recommendations on the optimum solutions for your operation. Find them on 08 9418 4952 or visit nexxis.com to see their extensive range of quality ultrasonic phased array testing systems including the highly regarded Omniscan MX2 which delivers high speed electronic scanning, improved inspection capabilities, multiple-angle inspection, optimised focusing and greater flexibility.