Try The MaggHD For A Change

In the field of remote visual inspection, seldom does a new piece of equipment make such a significant impact on so many different industries in such a short space of time.

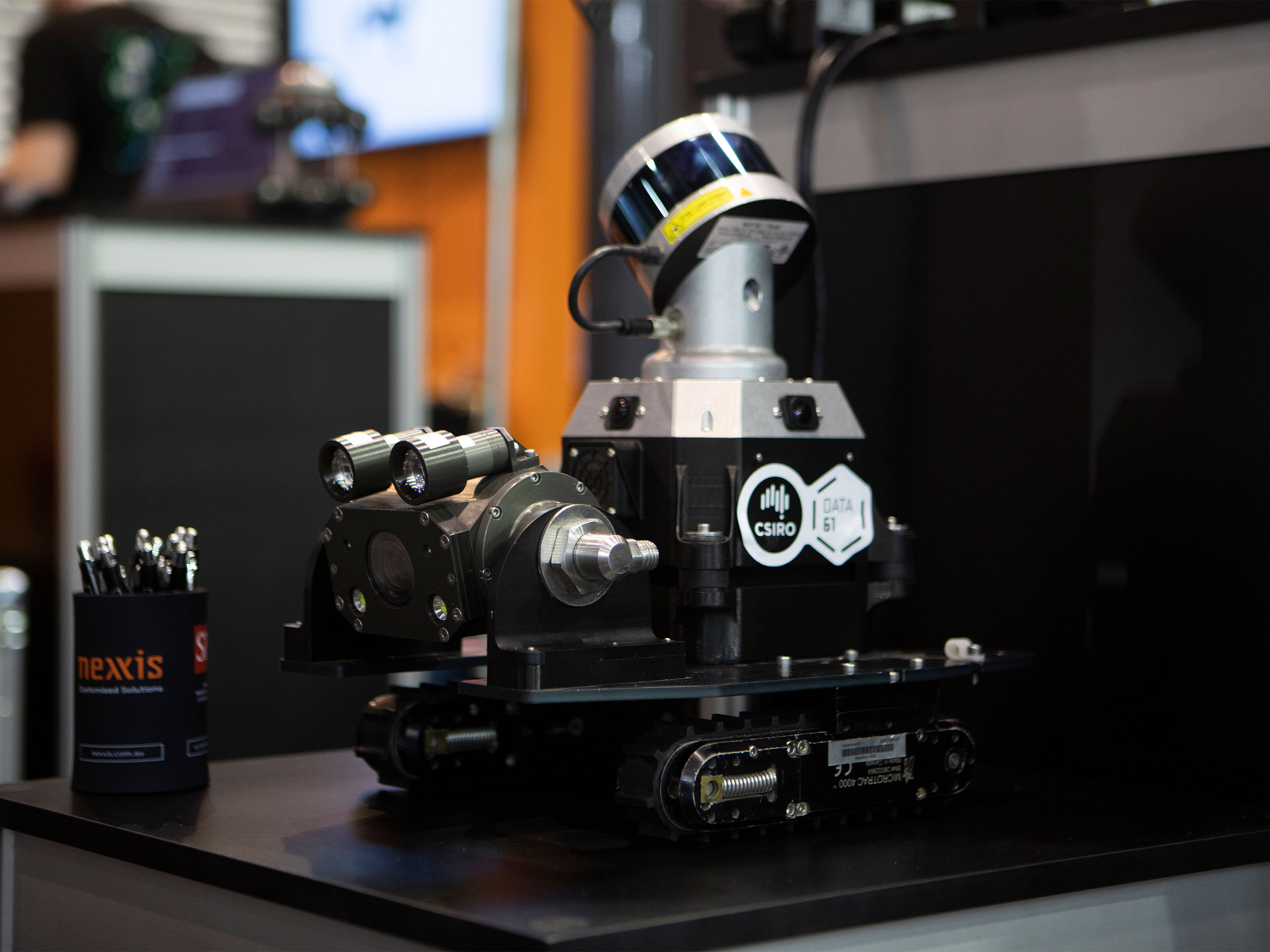

But then, the MaggHDTM video magnetic crawler is different. It’s a game-changer.

This miniature crawler was only launched a few years ago, yet it’s proven to be a gigantic success in a diversity of applications and is being acclaimed worldwide for its remarkable capabilities and versatility.

So should your operation try the MaggHDTM?

Well, if your RVI requirements involve confined spaces, limited entry points, inhospitable or hazardous environments or inspections that put humans at risk, then you’ll be interested to read about some of the situations where this powerhouse has made a substantial difference. You’ll also be interested to learn about some of the special adaptations that were made to this device in order to overcome specific application challenges.

The MaggHDTM is manufactured by global technical equipment leader, Inuktun, who has a long history of innovation and client collaboration to effect change and improvements in the field of RVI. The following examples illustrate their ongoing drive to develop more effective solutions to inspection challenges which in turn, change the way industries do business.

Oil and gas

The waterproof MaggHDTM is used at BP’s Thunder Horse oil platform in the US Gulf of Mexico to creep along pipes that connect the giant facility to the sea bed. A company representative said they wanted the robots to remove individuals from being in unsafe environments and that the efficiencies they gained by collecting data in this way were significant and that the safety factor was obvious. BP is the largest operator in the Gulf of Mexico and expects to roll out similar crawlers across all its Gulf of Mexico platforms in coming years.*

On another oil and gas major’s offshore platform, customisation through collaboration resulted in the MaggHDTM being able to be used with a 100% success rate. Inuktun technicians worked with the client and sub-contractors to design a custom vehicle chassis that allowed the device to drive beneath pipework and other obstacles on this complicated infrastructure without compromising manoeuvrability or inspection capability.

Pressure vessel inspection

Pressure vessel inspection is generally a cinch for the MaggHDTM, and even though the complex geometry of PV structures at a petrochemical facility in Texas presented some challenges, the Inuktun engineers customised a solution. Special extension arms were built to handle transition and traction challenges, with special NDT sensors to measure coating thickness and resistivity.

Wind turbine inspections

The size and construction of big, heavy blades of wind turbines make it impossible for technicians to manually inspect the units all the way to the confined space at the tip. But the MaggHDTM can inspect deep into the blade and with its HD zoom capabilities, can capture video and still images to the very end. This ability to inspect assets remotely to ensure their integrity and optimal operation save time and money – plus it eliminates human risk.

Nuclear storage cask inspections

A tall order from TN America for an inspection vehicle that could handle confined and radioactive areas outside of nuclear waste storage containers which also had extremely limited entry points and non-ferrous surfaces was no problem for Inuktun. Their engineers delivered a bespoke MaggHDTM with a tailored chassis to cope with the space restrictions, a motorised camera raise and an integrated infrared temperature sensor in the camera head for non-contact readings of the surface temperature.

These are just some of the unique situations where the capabilities and versatility of the MaggHDTM have enabled it to go deeper, further and higher to deliver high quality, reliable visual inspection results across a broad range of applications. It’s a modular system and the camera head can be removed from the vehicle quickly and easily and attached to a telescoping carbon fibre pole for quick viewing in almost any confined space including tanks, pressure vessels and manholes.

If it’s time for a change in the way your operation carries out visual inspections, perhaps it’s time to try the MaggHDTM. And if your specific application requires something extra special, you can always talk to the technical equipment experts at Nexxis about customising a solution.

We carry a wide range of leading brands of robotic crawlers and cameras, including the MaggHDTM plus all the optional extras and our experienced professionals are well-equipped to discuss flexible options for using these highly successful devices in your operation.