Tips & Tricks: Robotic Crawlers Overview

Using Robotic Crawlers for your Remote Visual Inspection is a good way to visually inspect and maintain your equipment and assets.

Tips & Tricks: Robotic Crawlers Overview

Using Robotic Crawlers for your Remote Visual Inspection is a good way to visually inspect and maintain your equipment and assets. The Crawlers offered by Inuktun are reliable, efficient and versatile and are used extensively for Energy, Mining, Oil & Gas, Aeronautics and Utilities industries.

Remote Visual Inspection

If your operation requires real-time inspection of voids, difficult to access areas, pipelines, tanks, container or other enclosed structures, then RVI provided by a Robotic Crawler can be an efficient and versatile way to conduct an inspection, without compromising the safety of personnel.

Here is a list of Tips & Tricks that can help you streamline your process when using the Inuktun range of Robotic Crawlers and accessories:

Tip #1: Choosing your Tracks

Crawler tracks come in a variety of different materials to suit a variety of environments. Here’s a quick guide on how to choose the best tracks for your crawler system:

- Brass:

- Higher weight for better traction

- Good chemical compatibility

(e.g. chlorinated solvents) - Non-sparking

- Stainless Steel:

- Higher weight for better traction

- Good chemical compatibility

- Best for nuclear decontamination

- Aluminium:

- Lightweight (bigger payloads)

- Ideal for vertical and/or magnetic crawlers

- Non-caustic environments

Tip #2: Long-Range Crawler

Sometimes you may have a pipe to inspect that runs greater than 2km and has limited access points. The Versatrax 300 is a perfect solution for long-range inspection, with the capability of travelling up to 2km or more. That gives the inspector the ability to enter the pipe at a single point.

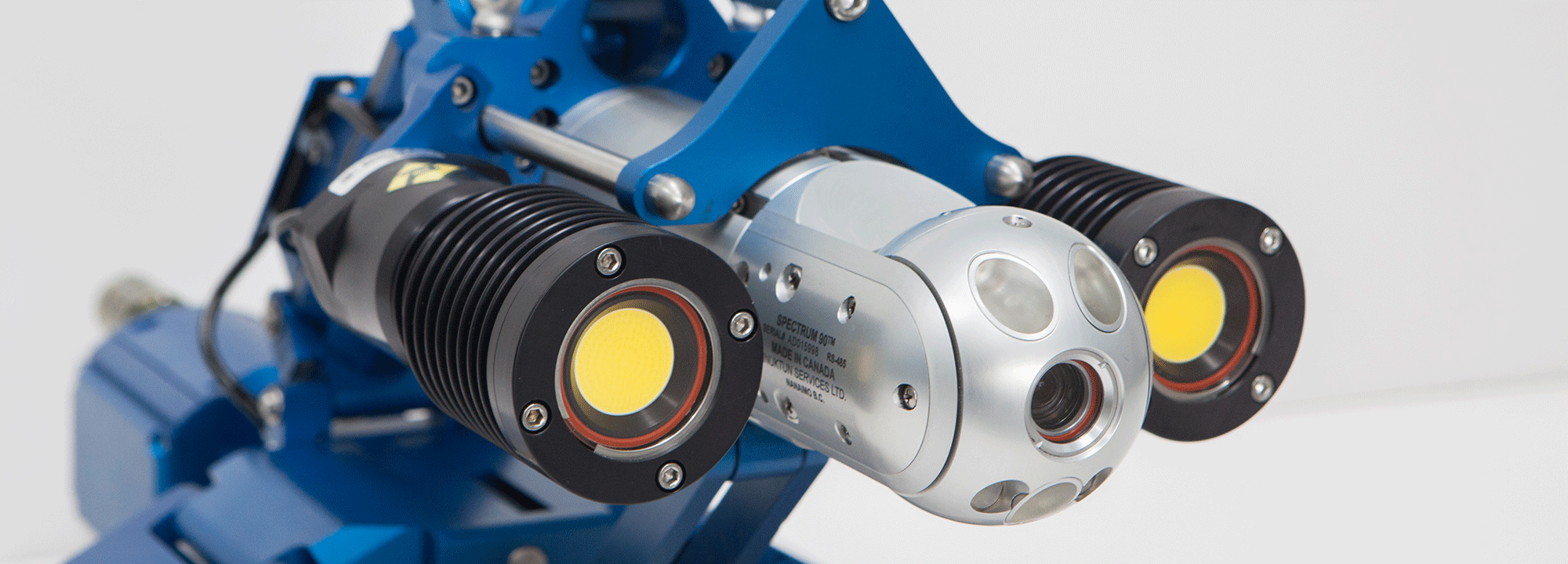

The Versatrax 300 is also waterproof up to 60m, can be fitted with 3 x cameras and a variety of sensors including sonar, laser profiling, flow rate and pressure sensors.

Tip #3: Reconfiguring the VT 100

The Versatrax 100 is perfect for pipe, tank or vessel inspections and is capable of being reconfigured to a variety of pipe diameters to ensure the tracks function effectively. Here’s how to adjust the tracks from the wide setting to a configuration more suitable to a smaller pipe:

- Locate and loosen the locking nut on the front of the Crawler

- Place hands on sides of tracks and apply firm, even pressure.

- Tighten the locking nut while holding the tracks in place. Having a second pair of hands available can be helpful, but with practice, this adjustment can be made by one person very easily.

Tip #4: Customizing your Crawler

Sometimes you may be looking for a customized configuration for your Crawler. While Inuktun provides pre-configured systems that will suit most needs, the range of tracks and accessories, allows your team to engineer the components into any number of customized setups to suit your needs.

Just like any vehicle, different systems are more suitable for different environments. The track system on a Bobcat, for instance, wouldn’t be suitable for driving on the beach. Inuktun provides standalone components, including the tracks, cameras and accessories like sensors and manipulator arms that allow your team to create their own innovative setups and systems.

The different Tracks available in both regular and extended lengths:

Standard Tracks – Width: 40cm / 15.7″

Extended Tracks – Width: 51cm / 20″

Tip #5: Common Uses for Robotic Crawlers

If you’re researching Remote Visual Inspection solutions for your company, it usually helps to know which other industries use Robotic Crawlers for RVI. Knowing that other industries or companies utilize crawlers for asset and equipment inspection in a similar way to the needs of your company, can help you make a decision about the best product. Here are just a few common uses that can point you in the right direction:

- Inspection of storage tanks, welds, HVAC, corrosion evaluation

- Inspections of reactor pressure vessels and surveillance during offloading and refuelling

- Reactor vessel inspections

- Railroad and truck tank cars

- Elevator and mine shaft

- Steam generator bowl and secondary side inspection

- Reactor coolant pump

- Nuclear fuel bundle Serial number verification

- Military Operations

- Search & Rescue

Tip #6: Getting your Crawler Vertical

There are a variety of crawler systems capable of travelling vertically up tanks or along pipes, poles and conduits. To help you decide which system is ideal for your inspection needs, it will help to see the crawler in action. Here are three different Crawlers in three different environments, each one quite unique.

1 – Versatrax Vertical Crawler

With an expandable, tripod chassis and three Microtracs, this crawler can remotely expand its tracks to travel vertically. Independent track control allows the crawler to navigate multiple bends and inbuilt LED’s keep things illuminated.

Image Source: Eddyfi Technologies

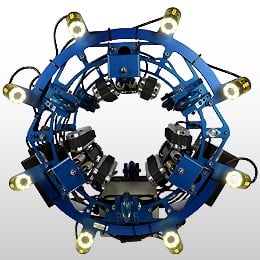

2 – Versatrax MicroClimber

Perfect for pilings, pipe, rope or guy-wires, this crawler is designed to climb on almost any inclined or vertical cylindrical structure. The crawler can be adapted for NDT devices, cameras or cleaning tools, but comes standard with eight Crystal Cam cameras so you won’t miss a thing.

Image Source: Eddyfi Technologies

3 – Versatrax 100 MicroMag & the NanoMag

Both these systems are fitted with a magnet and are capable of travelling vertically on metal pipes and structures. Perfect for ship hulls, pipes, tanks and other vessels, these crawler systems are also customizable and can accommodate a range of accessories including cameras, sensors and brushes.

Image Source: Eddyfi Technologies

We hope that this summary of our Tips & Tricks on Robotic Crawlers helps you make your decision about RVI. If you need help finding a solution that suits your business or project, don’t hesitate to get in touch and let our Operations Specialists help you determine the best fit for your needs.