The Use of Eddy Current Array Technology To Inspect Turbine Dovetails

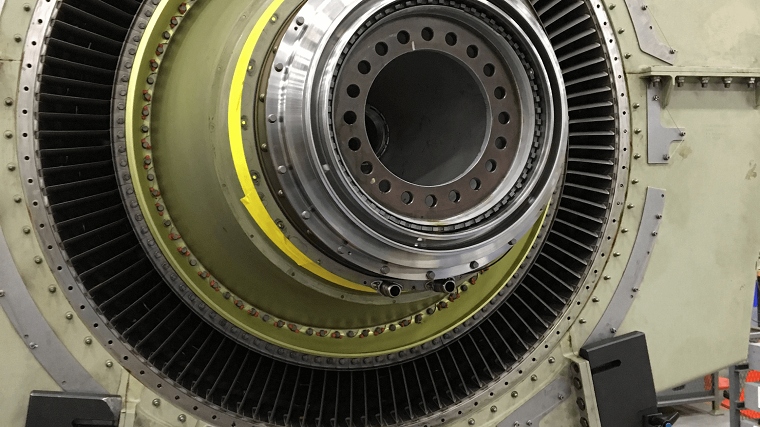

Condition-monitoring of turbine blades inside gas turbines used by the power generation industry is of crucial importance to ensure their safe operation and to extend the life of ageing equipment.

These enormous and complex turbine blades are subject to very strenuous environments and a range of factors can influence their performance and condition. High temperatures, high stresses and in some instances, high levels of vibration can all weaken the blades and make them more susceptible to failure. And although the blades are carefully designed to resist these conditions, they do need to be inspected regularly and thoroughly to ensure they remain reliable, efficient and safe.

Generally, the blades are attached to the rotor though male and female ‘dovetails’ or fasteners – a clever system of interlocking parts which create a strong joint. However, these dovetails are particularly prone to fatigue cracking and stress corrosion cracking (SCC), which is typically small and concentrated near the dovetail hooks.

If not arrested in the early stages, SCC can progress leading to the unexpected failure of metals which are normally ductile but which are subjected to tensile stress (such as those found in gas turbines). Hence, there is a critical need to identify the first signs of stress corrosion cracking and take swift remedial action.

The female portion takes longer to inspect and usually involves the use of robotic methods which can be slow, complex and expensive. Dovetails also come in many different designs and it’s not possible to check for minute cracks and characterise them with the appropriate level of precision using a single technique.

While attempts have been made in the past to use conventional eddy current pencil probes and penetrant testing (PT) to inspect for minute cracking, these have not been effective nor reliable given the geometries of dovetails.

Is there a solution?

Given the variance in their shape and size, dovetails generally require a customised solution – which eddy current array (ECA) technology provides. This technology is easy to use and eliminates the need for costly robotic solutions.

How does it work?

ECA uses a system known as multiplexing (grouping together several individual coils in one probe and then exciting them sequentially in order to avoid any interference from mutual inductance) to scan a wide inspection area. The coils are mounted inside a membrane which is spring-loaded to ensure constant contact with the dovetail, ensuring no defects are missed.

The probe contains precision encoders which use advanced high-performance software to locate and size defects in 2D and 3D scans, and the operator only needs a single pass to collect data. Precision computerised data recording, reporting and archiving are other key advantages over penetrant testing – and the C-scan imaging makes it easy to interpret results.

Advantages in a nutshell:

- Probe is supported by a rugged, compact battery-operated data acquisition unit

- Stable and easy to operate by a single user

- Only a single pass required over areas of interest

- Solution can be customised to specific dovetail profiles

- Environmentally friendly and safe to use – no chemicals required and no hazardous waste

- Comprehensive data recording and record-keeping

- Precise, accurate and reliable results

This ECA technology from Eddyfi Technologies has proved successful in detecting defects down to 0.38mm deep and 0.75mm in length, proving its worth in inspecting gas turbine dovetails which have highly specific requirements. But its application isn’t limited to gas turbines. Generator slots, rotor bores and bore holes are just some of the other applications where custom ECA probes have been successfully deployed to meet demanding and specific inspection requirements.

The industry professionals at Australia’s leading supplier of technical equipment, Nexxis, have a wealth of experience with all the different inspection technologies, including the most up-to-date innovations in ECA. They carry a range of advanced Eddyfi products and their flexible, value-driven approach will help you solve your operation’s specific inspection or testing challenge. Get in touch on 08 9418 4952 or visit nexxis.com to find out more.