Smarter tech, collaboration enhance Stork NDT services

ADVANCES in technology have assisted inspection and testing providers to improve service to their clients and enhanced the overall integrity of the industry.

That’s according to Stork Business Development Director Richard Stocker, who also sits on the board of directors for the Australian Institute for Non-Destructive Testing.

“There was a time when clients didn’t have a lot of understanding about the work that was being carried out and were just happy to get a heap of data and a report at the end of a project, but the market is changing,” Richard said.

“Now, with advances in robotic crawler technology and the ability to carry out visual inspections, they are taking on their own NDT specialists to work with providers, improving the quality, accuracy and integrity across the industry.”

Richard says clients are looking for innovative solutions and reduced cost, both of which Stork has achieved by working with Nexxis’ Solutions team.

“If you can reduce client downtime and the need to put people in hazardous areas while providing quality inspections with better results, it puts you well ahead of the game,” he said.

“We’ve used crawlers for quite a while but they were off-the-shelf models that didn’t always give us the flexibility we needed.

“Because of that, we might have knocked back a job if we didn’t have fit-for-purpose equipment, whereas now we can get Nexxis to customise a crawler precisely to the job requirements, giving clear data and unquestionable results to help make decisions.

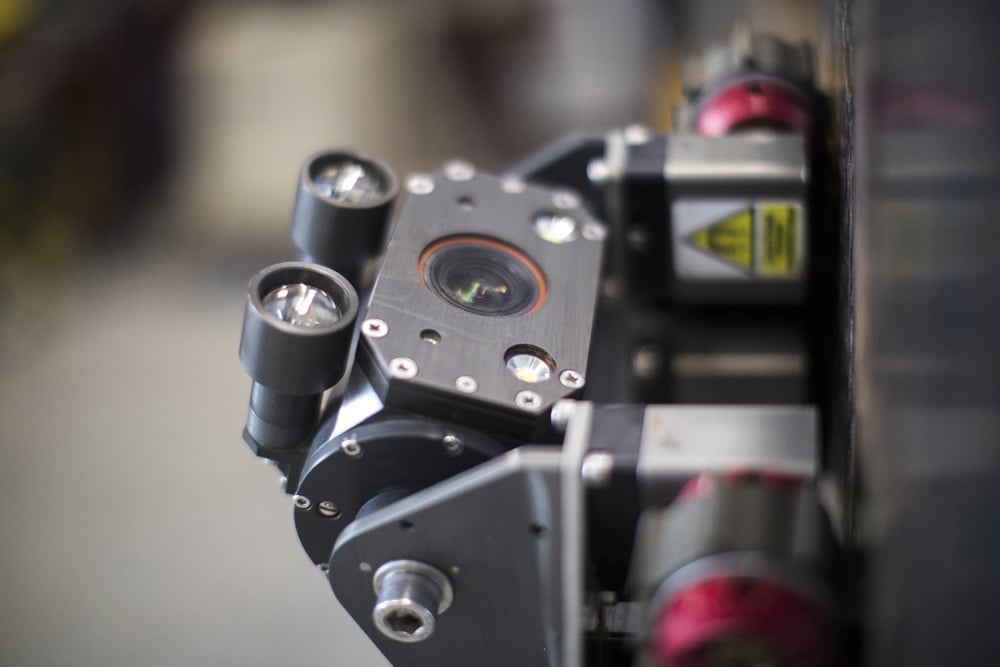

“Nexxis describes its equipment platforms as modular design or almost like Lego – you can remove and add components such as cameras, lasers, Lidar, manipulators, lighting and a whole range of advanced NDT to cater for things like different pipe diameters, bends, vessels and structures.

“We just throw the requirements at Nexxis and they come back with a fit-for-purpose solution giving us options, and provide our guys with all the training they need to operate it or come on site to assist with the implementation to ensure a positive outcome.”

Richard said Stork recently completed a project to carry out an internal visual inspection of an 80-metre slug catcher during a critical outage at a gas processing plant.

Previously, due to the risks of confined space entry, only the first four metres of the slug catcher had been internally inspected. External NDT inspection methods were considered but due to the time constraints, were deemed to be inefficient.

“With the assistance of Nexxis, Stork deployed a modified MaggHD internal crawler which could access the entire length, negotiate obstacles and provide full HD video,” Richard said.

“It was the first thorough inspection of the entire slug catcher that had been carried out and gave the client full confidence in its condition.”

Richard said an additional benefit of working with Nexxis was that it gave Stork the capacity to move rapidly into contracts without the need to raise large capex requests or wait for equipment.

“We might need additional stock for short-term projects or where there’s not a lot of ramp-up time,” he said.

“Nexxis has some unique models that offer the flexibility to suit our business and ultimately mean we are using the latest technology, benefits that we are able to pass on to our clients. They also have the ability to support us in a scale-up through peeks and scale-down during quiet periods.

“The level of technical support provided by Nexxis is helping us win more jobs and deliver outstanding results.”

–ends–