RVI & NDT Essentials: What Do I Need And Why?

With the global growth of the RVI and NDT markets, we’re seeing relatively rapid advancements in the technological features, ease-of-use, versatility and portability of the devices available.

With an expanding array of options and the merging of product technologies (eg. the Mentor Visual IQ Borescope incorporating 3D Phase Measurement), the question for companies conducting NDT and RVI programs is; What devices are available? – and which one is the best solution for my project?

In order to answer this, THE FIRST QUESTION to ask is; what do I need to test or observe?

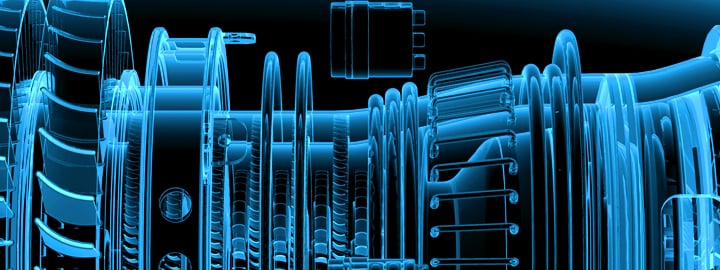

Whether inspecting a turbine, assessing weld integrity or visually observing hard to access areas, your equipment choice is going to be determined by what you need to assess and what data you need to create during that assessment.

Though traditionally difficult to categorize RVI/NDT, we will attempt to broadly outline the different product types and their uses.

Robotic Crawlers: By far the coolest of the RVI range and with a variety of versions available, Robotic Crawlers are great for visually inspecting pipes in civil infrastructure, oil and gas or mining as well as assessing tanks and ship hulls.

Video Borescopes: These devices are extremely portable, and with recent advancements are able to take 3D Phase Measurement as well as traditional visual data. Used extensively in aerospace for inspecting turbines, Video Borescopes are also well-suited to any application that requires non-intrusive visual inspection in tiny, difficult to access spaces.

Laser Alignment: As the name implies, there are a range of products that have been developed for belt and shaft alignment using laser technology. Easy Laser produce a variety of measurement tools that are optimized to maintain machinery and avoid needless wear and tear.

Radiography & CT: This method of scanning is highly effective in penetrating material to check for hidden cracks and flaws that are invisible to visual inspection. Any industrial infrastructure that is exposed to the elements or continuous wear and tear can be assessed with Radiography and CT scanning.

Push-Rod Camera Systems: Like Borescopes, Pushrod Cameras are designed for visual inspection – though the devices are larger, they are more durable and capable of penetrating pipes to a far greater distance. Civil infrastructure like sewage and plumbing is a common application.

Ultrasonic Testing (UT): Ultrasonic testing is a family of NDT used to detect flaws, measure thickness or characterize materials. It is often used in manufacturing, aerospace, metallurgy and the automotive industries.

Eddy Current: This form of inspection uses electromagnetism for rapid, easy and cost-effective scanning of welded structures, raw materials and finished products to detect surface and sub-surface flaws.

PMI (XRF): For quick, reliable and accurate identification of materials and elements, XRF (X-Ray Flourescence) is a great, portable solution. Used in forensic science and archaeology, XRF testing is used widely by geologists in the mining and oil and gas industries.

As the NDT and RVI technologies overlap somewhat, and as more of the available devices offer a greater range of testing, it’s safe to say we’re going to see the number of devices condense in the coming years. So don’t be surprised if this list gets updated before the next quarter. If you’re thinking about an NDT or RVI program for your project, get in touch and let one of our Operations Specialists talk you through the best solution for your needs.