New Solutions for Inspection & Maintenance In The Petroleum & Petrochemical Industries

Inspection and maintenance of equipment and assets within the petroleum and petrochemical industries has always been a challenge. There is, of course, the aspect of cost, which every company needs to address in order to remain competitive. And then there’s the equally important element of human safety.

Advancing technology is bringing about new solutions to all facets of the industry. When looking at the latest on offer, as well as those in the pipeline, it’s necessary to evaluate the three following areas to gain full appreciation of how these will provide benefit.

- Cost

- Current and future technology

- Customer value

1. Cost

Historically, one of the most dominant factors regarding inspection and maintenance has been that of asset downtime. In order to ensure safety of workers and the highest level of equipment maintenance it’s been necessary to shut down equipment to prepare and clean for humans to safely enter. Such downtime leads to loss of revenue. In addition, such lengthy procedures don’t lend themselves to the proactive steps of carrying out inspection over and above that which is legally required.

2. Current and future technology

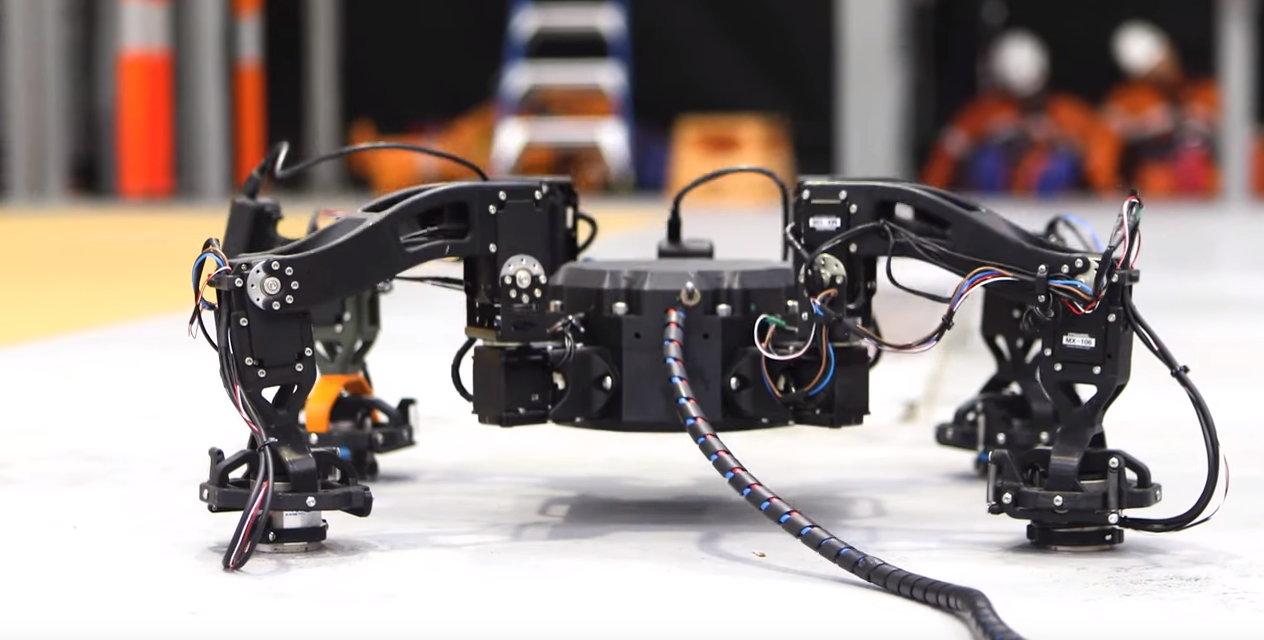

Advancing technology is the cornerstone of new solutions for inspection and maintenance. Robotic inspection is proving invaluable, with advantages not only bringing about significant cost reduction, but also that of increased workforce safety. Whilst current use of inspection robots is carried out by remote control, the reality of autonomous equipment that can carry out such tasks without the need for much (or any) human intervention is already in the making. It’s highly likely that such tools will become reality in the not too distant future.

3. Customer value

With new solutions that include remote and online inspection, operations and maintenance brings about significant customer value. Businesses need to be able to not only reduce cost and increase safety, but now have the added challenge of environmental impact. By taking advantage of the latest technology all three of these crucial aspects can be addressed.

Other areas of focus are those of the remote operation of unmanned sites, the ability to keep equipment online during inspection processes, better visualised inspection of more complicated structures and the ability for robotic tools to negotiate hazards and adapt and overcome different surfaces and terrain other than flat landscapes.

New solutions and industry impacts

When it comes to costs, the use of robotics for inspection and maintenance drastically reduces the need for equipment downtime:

- Less preparation time as there will be no need to make confined spaces safe for human entry

- Negates the need for the erection of scaffolding for humans to work at height or within piping systems

- Can reduce the need for transporting crews to a remote/offshore site.

Inspection by robot can be utilised in many different scenarios:

- Tank coating inspection

- Removal of build-up of deposits

- Crack detection

- Direct visual inspection of a surface out of line of sight

- Inspection of insulated piping

- Proactive inspection, as opposed to reactive maintenance once a problem has been detected.

Naturally, such advancements bring with them the need for further technological solutions, many of which are already the focus of much scientific endeavour.

- The guarantee that an autonomous inspection robot has no chance of creating any hazardous situations. They must also be able to work safely in the presence of humans. In some cases there could be a preference for semi-autonomy, rather than full, allowing a human remote operator to carry out selected tasks and only allowing the tool to autonomously undertake particular assignments.

- Techniques such as acoustic resonance, UT and electromagnetic inspection could be needed when it’s not possible for visual inspection. Therefore any current procedures will need to have the ability for robot deployment.

- One of the advantages of robotic inspection is that of the speed and accuracy of data produced. It’s highly likely that such rapid collection will be unsuitable for humans to process. Therefore an automated procedure will be necessary, as will the ability to interpret, store and retrieve such data.

The potential of robotics to transform inspection and maintenance tasks over the near future is immense. Perth-based company, Nexxis, are not only at the forefront of the provision of such equipment, but offer a unique service whereby we help companies determine the exact solution that will address their particular needs. Such a bespoke approach towards the utilisation of the next generation of equipment has led to us becoming the preferred provider for many industry leaders as they determine steps forward in this ever more competitive industry.

Contact us to find out how our experts can help your business understand and best take advantage of such technology.