What is Combination Soft Foot?

Any aligner knows that not properly correcting soft foot during a precision shaft alignment leads to frustration and anguish, not to mention wasted time. Soft foot is such a problem there has been numerous articles on The Alignment Blog the past few years about the subject. The articles discuss the many causes of soft foot and correcting “parallel” and “angular” soft foot, but what about correcting “Combination” Soft Foot? Never heard of it? Me neither until recently.

While performing the pre-alignment steps on a 200 HP motor pump set, a customer found obvious soft foot at the motor’s rear feet. A 0.005” thick shim fit under the right rear foot to correct the parallel soft foot however the shim pack was still loose. Further checks with a feeler gauge also revealed an angular soft foot of 0.015”! One leg of a 0.015” thick shim was cut off, leaving the safety tab, and inserted under the foot to correct the angular soft foot. The left rear foot was found to have 0.005” angular soft foot which was also corrected.

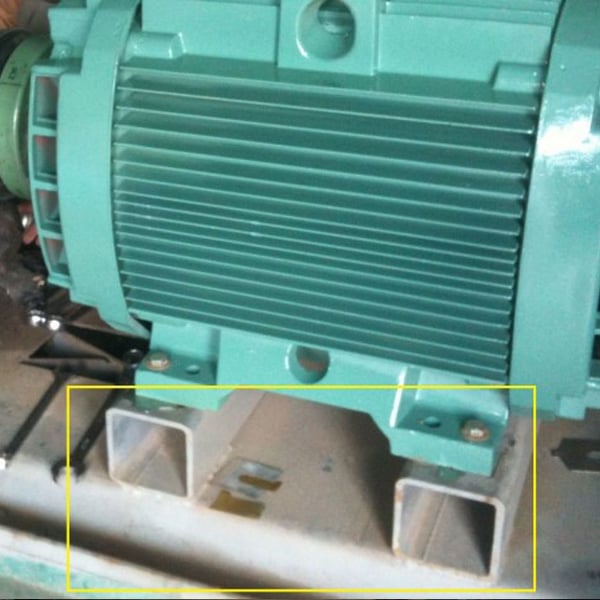

So what was the cause of the “combination” soft foot? The sub base, which in this case is structural square tubing under the motor feet.

Structural tubing is not always the best choice for a sub base as the sides of the square tubing are not necessarily flat and the thinner wall thickness of the tube can deform. In this case it appears the tubing may have deformed slightly when welded to the base causing the non flat surface under the rear motor feet.

When dealing with soft foot anything is possible, whatever the type, it needs to be corrected.

*This article was originally created by Brad Case