The Benefits Of Ultrasonic Testing For Composite Structures

It is imperative that structures and components are tested and evaluated in order to maintain the highest levels of safety, performance, quality and regulatory compliance.

In industries such as aerospace and aviation where composites are extensively used, it is imperative that structures and components are tested and evaluated in order to maintain the highest levels of safety, performance, quality and regulatory compliance.

Composites are made by combining two or more materials which have markedly different physical or chemical properties in order to maximize their useful properties and minimize their weaknesses. The component materials don’t lose their individual identities, but rather act in concert – usually when the fibres of one material are bound tightly into the matrix of another material – to make a powerful ‘team’ which generally offers the benefits of low weight, high strength, added efficiency and durability.

Historically, composites were seen as ‘space-age’ materials but nowadays, they’re part of everyday life and are found everywhere from aircraft, motor vehicles, bridges, architectural components, golf clubs, furniture, microwave ovens and boats.

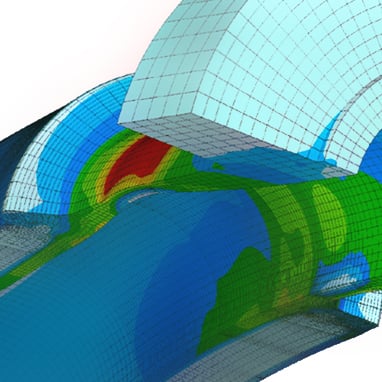

Ultrasonic testing (UT), a completely non-destructive testing technology, is widely used for testing composite structures and components because it enables highly accurate results for locating and sizing flaws, cracks, voids and other defects. It works by transmitting high frequency sound waves, most commonly ranging from 500 KHz to 20MHz (through a transmitter and receiver circuit) into the part and then analysing the ultrasonic signal that is received. This information enables the thickness and the internal structure of the part under test to be measured and any evidence of hidden cracks or flaws to be uncovered.

There are two common approaches of ultrasonic inspection, namely pulse-echo and through transmission, both of which can be used for non-destructive testing of composite structures. Pulse echo uses a single test method that generates the pulses as well as receives the return signal, whilst through transmission uses two transducers, one of which emits the ultrasonic vibrations whilst the other receives them on the opposite side of the test item.

Benefits of UT for composite structures:

- High-speed scans

- High resolution

- Highly accurate

- Ability to detect a variety of flaws, including cracks, voids, disbonds and inclusions

- Capable of sizing defects

- Repeatability

- Reliable

- Versatile

- Can be used on small items (portable contact inspection) as well as large items (automated inspection)

- Ideal for use where the same part design must be tested repeatedly eg on an assembly line.

- Only requires access to one side of the part under test

- No health hazards associated with the testing process

Ultrasonic testing does, however, have some potential limitations in that it requires a skilled operator to set up the gauges and interpret the results properly. That said, the benefits far outweigh the potential disadvantages which is why UT is an indispensable NDT method for a wide variety of materials, not just composites, across many different industries

Nexxis supply an extensive range of UT equipment for the fast and accurate detection, location and sizing of defects which may be hidden deep in industrial applications. Our versatile ultrasonic flaw detectors, as well as a range of other quality non-destructive testing equipment, is available for rent or purchase now or contact us today for a no-obligation chat.