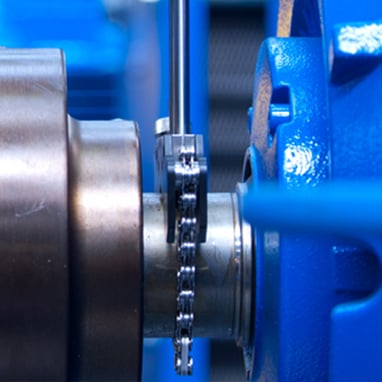

Advantages Of Laser Alignment Over A Dial Gauge

Switching to a laser alignment system over a dial gauge is a smart move that will save you time and money and also ensure a long and efficient lifespan for your machinery. Of course, not every application is suited to a laser indicator and dial gauges can still have their place, but for a great deal of alignment work, a laser system is the ultimate way to go and a worthy investment. Here are the top 5 advantages a laser alignment system offers over a dial gauge.

Easy to Use Even for Beginners

A dial gauge requires precise use and often needs complicated calculations. Dials can take a long time to get used to so for a less trained worker, there’s a lot more room for error. Laser systems are simple to use and require a minimum of training. It’s still important for the novice technician to learn the principles of correct alignment, but with a laser system that becomes a much more straightforward task.

With Easy-Laser E710 you can rest assured your machinery is precisely aligned, operating at maximum efficiency. Optimal machine alignment eliminates downtime saving you time and money on operations. You’ll also be saving on easily avoidable machine repair and saving big money on energy costs.

A Laser System Automatically Compensates for Thermal Growth and Shims

Compensating for thermal growth can be a difficult trick when measuring with dial gauges. A laser measurement system takes away all of the guesswork and adjusts automatically meaning you’ll always be getting a much more accurate and reliable measurement. Laser systems also automatically calculate for shims and adjustment values.

Quick and Easy Set-Up of Fixtures

A laser system is ready to go in a lot less time than it takes to set up a dial system. Dial gauges often require special fixtures for each machine whereas laser systems have a single set for all applications. Dial gauges also tend to drop, affecting the accuracy of the readout. With a laser system, you don’t have to worry about play and slack.

Measure with a Smaller Shaft Rotation

A complete measurement using a dial gauge often requires at least a 180-degree rotation or even a full 360 rotation. With a laser alignment system, a complete measurement can be taken with just a 40-degree rotation. This makes alignment really easy and quick, especially if machine parts are in the way of preventing a full rotation.

Consistent Results and Easily Recordable Data

With a laser system, you’ll always get the same results regardless of the technician doing the measuring, and all the data is stored simply and quickly and is easily transferred into your computer.

For modern machinery, a laser alignment system is the best choice for fast, reliable and accurate alignment that minimises downtime and makes sure you get the absolute best out of your machinery.

Find out more about our laser alignment systems or contact us today for a no-obligation chat.