7 Tips To Make Your V Belts Last Longer

V belts don’t generally attract much attention, but you’ll find that a little effort will go a surprisingly long way when it comes to maintaining optimum efficiencies, extending their life, reducing maintenance costs and preventing machine breakdowns.

Here are seven tips to make your V belts more efficient and last longer.

Use the correct installation procedures

It’s tempting to install a new V belt by simply rolling it onto the drive. This may save a few minutes, but it’s actually extremely risky if you don’t loosen the motor first. In addition to being unsafe, belts and sheaves can get damaged and you’ll be putting excessive loads on the belt and the support bearings and shafts.

Choose the right sized belt

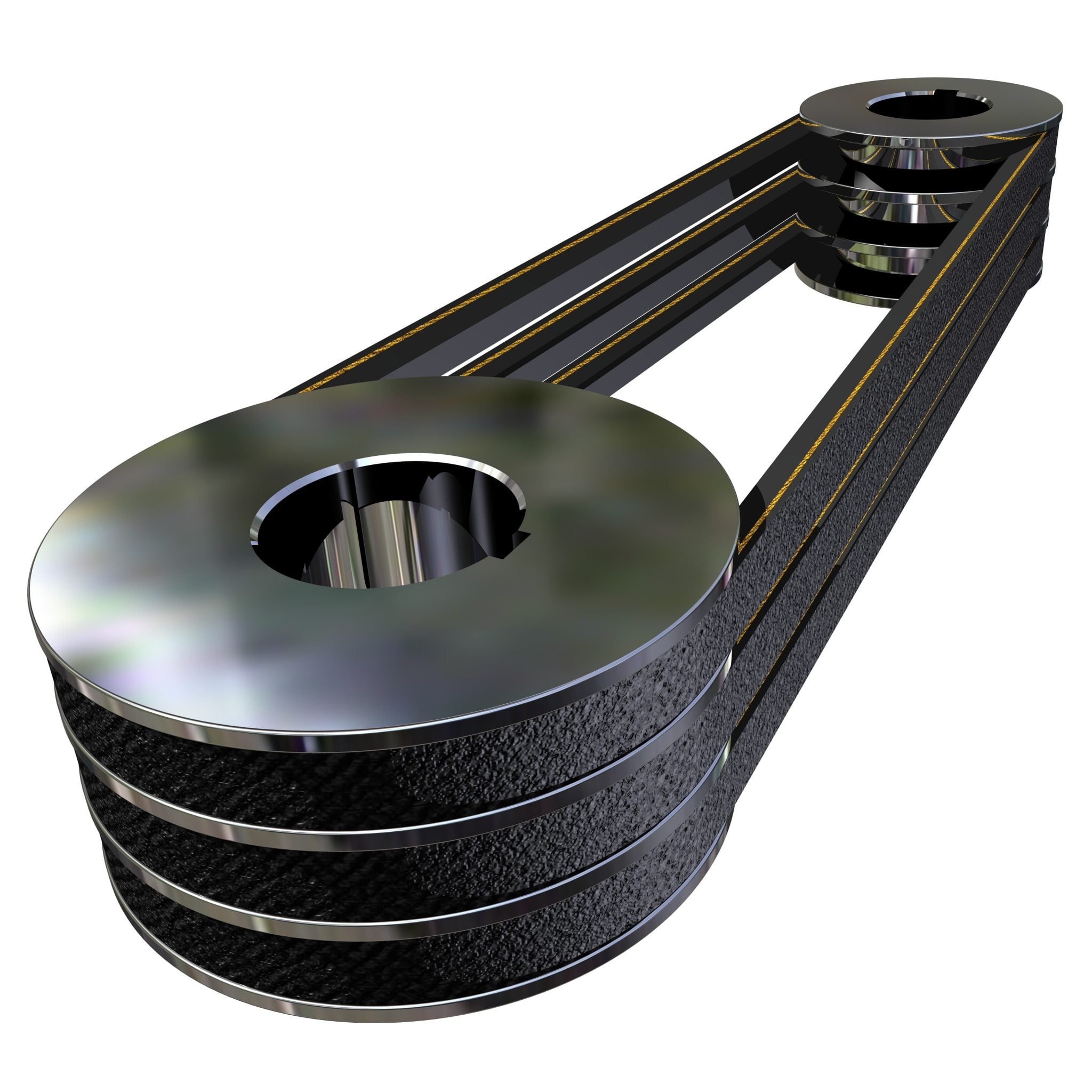

V belts have undergone significant technological development over the years in terms of new materials, construction methods, tensile cord advancements and cross-section profiles. They come in many different sizes, widths and profiles, and for optimum performance, you need to choose one that is appropriate to your application. A loose-fitting belt will negatively affect its efficiency and its life, so make sure the sheave grooves match and that it fits well.

Regularly check sheaves for wear

Surprisingly, many users replace V belts repeatedly without bothering to check the sheaves for signs of wear. Things to look out for include groove sidewall cupping and/or a polished groove sidewall with ridges. Worn, broken or damaged sheaves can reduce belt life by as much as 50% so they need to be replaced immediately. Don’t overlook sheave wear by simply re-tensioning the belt, rather get yourself an inexpensive sheave-groove measuring tool or gauge – it will save money and prolong the life of your belt.

Align sheaves properly

Proper sheave alignment is an important step in making V belts last. A laser tool is the fastest and most accurate means of ensuring horizontal and vertical alignment. There are many different models of professional laser tools available for belt alignment, all of which will result in reduced pulley, belt, bearing and seal wear, reduced vibration levels and increased efficiencies.

Tension belt properly

A belt tension tool is the best way to tension belts properly and makes your belt last longer. If you rely on ‘feel’, you may find it difficult to achieve the right tension and this will affect the life of your belt. If the tension is too little, it will result in high temperatures and excessive noise causing the belts to slip. If tension is too much, the band can break and bearing life will be dramatically reduced.

Ensure appropriate ventilation

One of the keys to long belt life is to keep the temperature as low as possible. To mitigate the high heat generated by the continuous flexing around sheaves etc, make sure the belt guarding area is properly ventilated.

Always check tension after break-in

Belt tension can change once the belt has heated up and stretched a little, so it’s really important to do a quick check and tighten if necessary to ensure the tensioning is correct. Many mechanics don’t do this, but it is a really important step in substantially increasing the life of your V-belt. To maintain horizontal angular alignment, it’s best to use a laser tool.

High loads, high temperatures, incorrect tensioning, worn sheaves, misalignment and dirt, oil and grease between the belt and the sheaves are all things that damage the efficiency and the longevity of your belt. Taking the time to do a few things during installation and maintenance of your V belt can make your V belts last longer, prevent machine breakdowns and avoid unnecessary and unplanned stoppages.

In addition to high-quality laser alignment instruments, leading technical equipment supplier, Nexxis has a wide range of non-destructive testing and inspection tools which can help your operation save time and money, increase efficiencies and meet productivity goals. For more information on a customised solution to meet your specific needs, contact us today.